2025 Top Hydraulic Equipment Trends You Need to Know for Your Business

As we approach 2025, the landscape of hydraulic equipment is evolving at a rapid pace, driven by technological advancements and changing industry demands. Understanding these trends is crucial for businesses that rely on hydraulic systems to enhance their operations and maintain a competitive edge. From increased automation to the integration of digital technologies, the future of hydraulic equipment is being shaped by innovations that promise to optimize performance, improve efficiency, and reduce environmental impact.

In this article, we will explore the top hydraulic equipment trends that are expected to dominate the industry in the coming years. By examining these developments, businesses can better prepare for the challenges and opportunities that lie ahead. The focus on sustainability, smart technology integration, and enhanced safety features will be highlighted, providing insights into how these trends can influence operational strategies. Adapting to these changes will not only ensure compliance with industry standards but also drive growth and resilience in a dynamic market environment.

Key Innovations in Hydraulic Equipment for 2025

As we look towards 2025, the hydraulic equipment industry is on the cusp of significant transformations driven by innovative technologies and sustainability mandates. A key focus is the integration of smart hydraulic systems that leverage IoT (Internet of Things) technology. These smart systems allow for real-time monitoring and analysis, helping businesses manage hydraulic fluid levels and performance efficiently. According to a report by MarketsandMarkets, the hydraulic systems market is projected to grow from USD 45.36 billion in 2020 to USD 63.12 billion by 2025, emphasizing the increasing demand for smart, efficient technologies in this sector.

Another transformative trend is the growing emphasis on environmentally friendly hydraulic fluids. With stricter regulations surrounding environmental impact, manufacturers are developing biodegradable hydraulic fluids that maintain performance while reducing ecological risks. The Global Hydraulic Fluid Market report projects that the demand for environmentally acceptable fluids will rise by over 25% in the coming years, indicating a pivotal shift in material choices. Additionally, advancements in manufacturing technologies, such as additive manufacturing and precision machining, are enabling the production of lighter and more efficient hydraulic components, which are essential for aerodynamic and energy-efficient equipment designs.

These innovations not only enhance operational efficiency but also align with global sustainability efforts. The continued evolution of hydraulic equipment in response to these trends will be crucial for businesses aiming to stay competitive in a rapidly changing landscape.

2025 Hydraulic Equipment Trends

Sustainable Practices in Hydraulic Equipment Manufacturing

Sustainable practices in hydraulic equipment manufacturing have become increasingly essential as industries strive to reduce their environmental impact. According to a report by the International Society for Automation, hydraulic equipment accounts for up to 30% of energy consumption in some industrial sectors. Consequently, the push toward sustainable practices is not just a regulatory necessity but also an opportunity for cost savings and efficiency improvements. Manufacturers are investing in eco-friendly materials and energy-efficient components, which can significantly lower the overall carbon footprint associated with hydraulic systems.

In addition, the adoption of green technologies is transforming production processes. A recent analysis from Grand View Research highlights that the global market for sustainable hydraulic equipment is projected to grow by 15.2% annually until 2025. Innovations such as biodegradable hydraulic fluids and energy recovery systems are gaining traction, as they contribute to enhanced system performance while minimizing pollution. By transitioning to sustainable practices, hydraulic equipment manufacturers can not only comply with environmental regulations but also meet the growing demand from consumers for greener products. This shift is pivotal in promoting long-term sustainability within the industry.

2025 Top Hydraulic Equipment Trends You Need to Know for Your Business - Sustainable Practices in Hydraulic Equipment Manufacturing

| Trend | Description | Impact on Sustainability | Forecasted Adoption Rate by 2025 |

|---|---|---|---|

| Smart Hydraulics | Integration of IoT and AI to enhance efficiency. | Reduces energy consumption significantly. | 70% |

| Biodegradable Fluids | Shift from petroleum-based fluids to environmentally friendly alternatives. | Minimizes environmental damage in case of leaks. | 60% |

| Energy Recovery Systems | Systems that capture and reuse energy during operation. | Reduces overall energy usage and costs. | 65% |

| Modular Equipment Design | Equipment designed for easy upgrades and repairs. | Lowers waste and extends equipment life cycle. | 75% |

| Automation and Robotics | Use of automation for improved precision and productivity. | Enhances efficiency while reducing human error. | 80% |

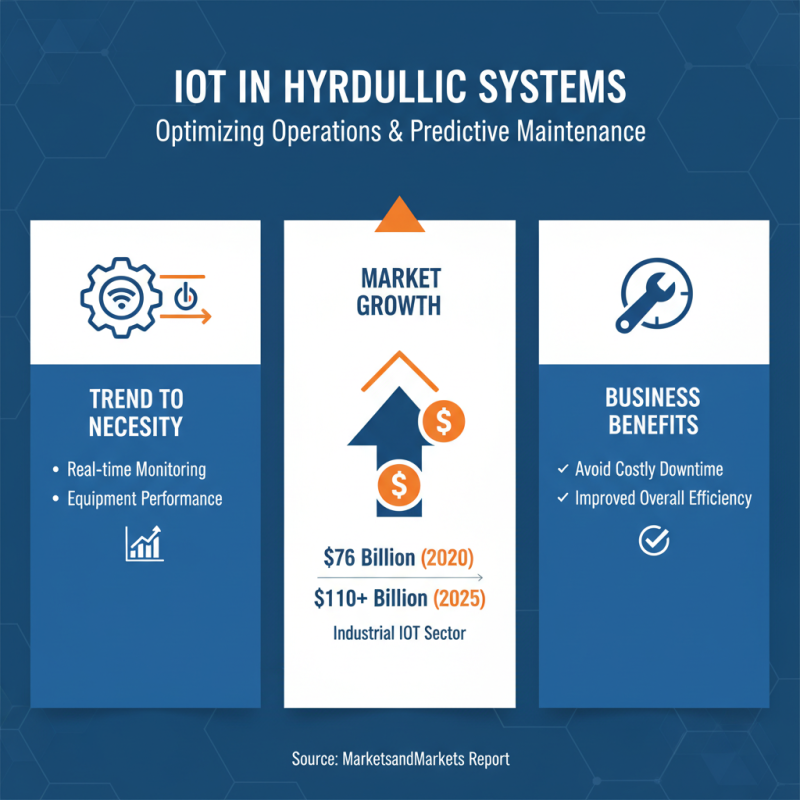

Integration of IoT Technologies in Hydraulic Systems

The integration of IoT technologies in hydraulic systems is not just a trend; it's becoming a necessity for businesses looking to optimize their operations. According to a recent report by MarketsandMarkets, the IoT in the industrial sector is projected to grow from $76 billion in 2020 to over $110 billion by 2025, highlighting the increasing importance of connectivity. Hydraulic systems equipped with IoT sensors enable real-time monitoring of equipment performance, leading to predictive maintenance. By implementing such technologies, businesses can avoid costly downtime and improve overall efficiency.

Incorporating IoT into hydraulic systems can also lead to significant increases in energy efficiency. A study from the International Energy Agency indicates that smart technologies can enhance energy savings by up to 15% in industrial applications. The ability to monitor hydraulic fluid temperature, pressure, and flow rates can ensure that hydraulic systems operate within optimal ranges, minimizing unnecessary energy consumption.

Tips: To successfully incorporate IoT into your hydraulic systems, start by evaluating your current equipment and identifying areas where sensors can provide valuable data. Additionally, consider investing in training for your staff to ensure they are equipped to handle the new technology efficiently. Building a culture that embraces digital transformation will allow you to fully leverage the benefits of IoT in hydraulic systems.

Trends in Hydraulic Equipment Maintenance and Safety Standards

The importance of maintaining hydraulic equipment cannot be understated, especially as industries turn their focus toward sustainability and safety. As regulations evolve, businesses must adapt their maintenance practices to meet new standards. Regular maintenance checks not only prolong the lifespan of hydraulic equipment but also minimize the risk of accidents, ensuring a safer working environment for all employees. Implementing a proactive maintenance schedule is vital to comply with the improving safety protocols across various sectors.

Tips for effective hydraulic equipment maintenance include conducting routine inspections to identify signs of wear and tear early. Keeping detailed records of maintenance activities can help spot trends and forecast when components might need replacing. Additionally, training employees on proper operational techniques ensures they understand how to handle equipment safely, reducing the likelihood of misuse that can lead to injuries or equipment failure.

Safety standards are continuously being updated, pushing businesses to stay informed about the latest regulations. It's essential to stay ahead of these changes by participating in relevant industry workshops or collaborating with safety organizations. Keeping all employees educated and aware of these trends not only enhances compliance but also fosters a culture of safety within the organization, ultimately safeguarding both personnel and equipment.

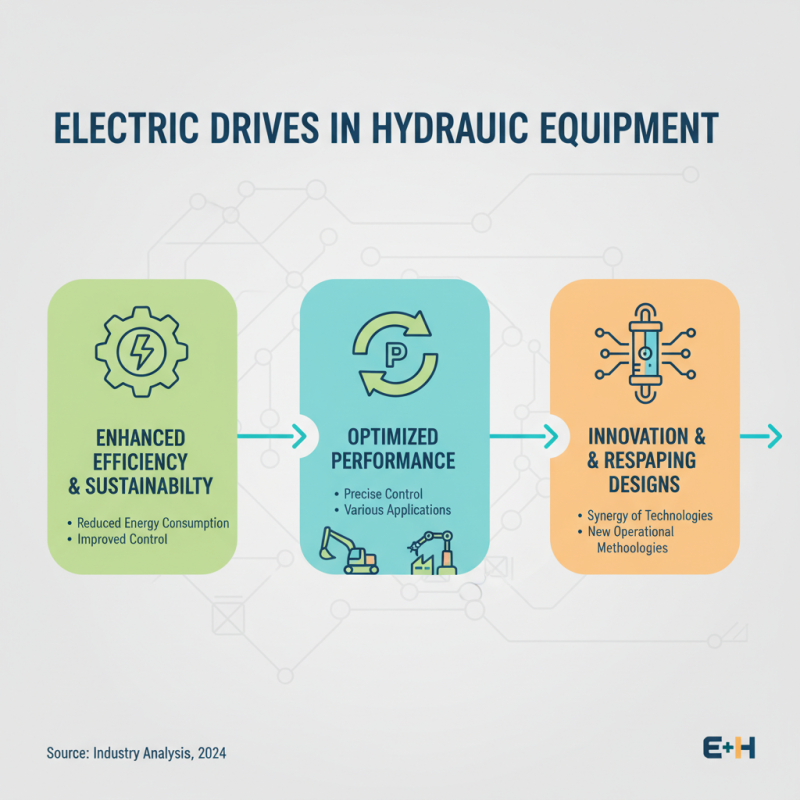

Impact of Electric Drives on Hydraulic Equipment Design

The emergence of electric drives in hydraulic equipment design marks a significant evolution in the industry, aiming to enhance efficiency and sustainability. These electric systems not only promote reduced energy consumption but also offer improved control over hydraulic functions. By integrating electric drives, manufacturers are able to optimize performance, leading to precise control in various applications, such as construction machinery and industrial automation. The synergy between hydraulic and electric technologies is fostering innovations that are reshaping traditional designs and operational methodologies.

Moreover, as industries increasingly prioritize eco-friendliness, the shift toward electric drives addresses the pressing need for greener solutions. Electric drives minimize hydraulic fluid usage and reduce emissions, aligning with global sustainability goals. This integration also results in quieter operations, addressing noise pollution concerns in urban environments. As businesses adapt to these changes, they gain competitive advantages through enhanced productivity and cost savings, showcasing the transformative impact of electric drives on the future of hydraulic equipment.

Related Posts

-

Understanding the Essential Role of Hydraulic Parts in Modern Machinery

-

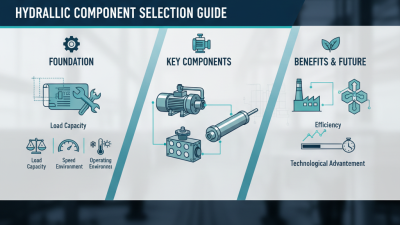

How to Choose the Right Hydraulic Components for Your Applications

-

Unveiling the Future of Fluid Power Hydraulics in Sustainable Engineering

-

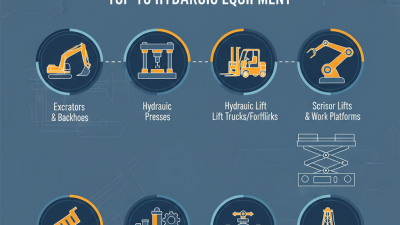

Top 10 Hydraulic Equipment You Need for Your Business Success

-

Top 10 Essential Hydraulic System Components for Optimal Performance

-

Innovative Solutions for Fluid Power Hydraulics Efficiency

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us