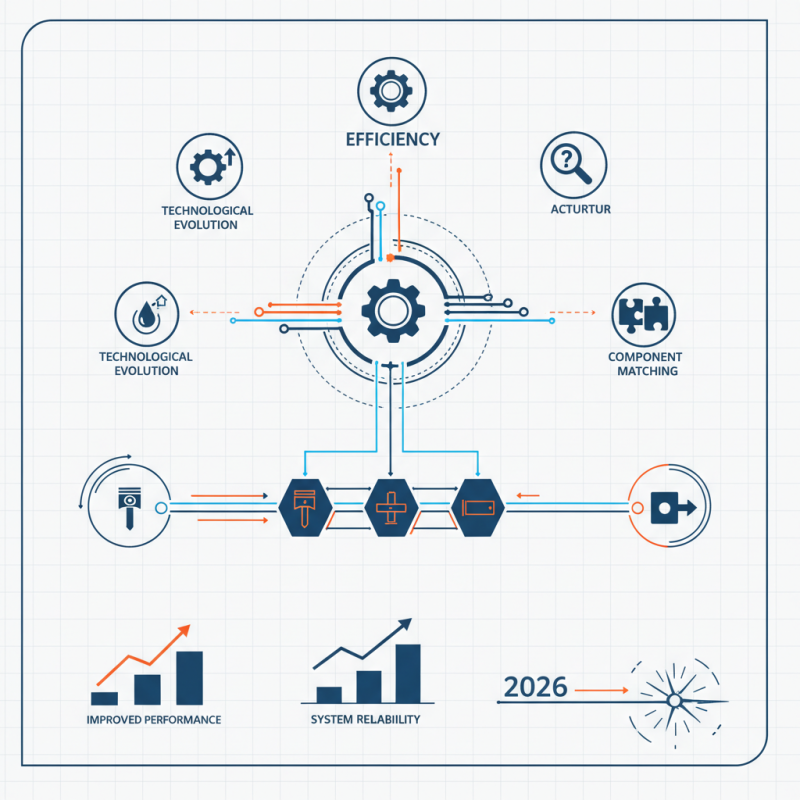

2026 Best Hydraulic Components for Optimal Performance?

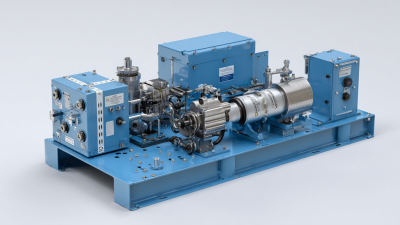

In the world of hydraulic systems, the efficiency of hydraulic components is vital. Renowned expert Dr. James Hargrove states, "The right components can make or break your system's performance." As industries evolve, so does the technology behind these components. Selecting the best hydraulic components for 2026 requires careful consideration of advances in the field.

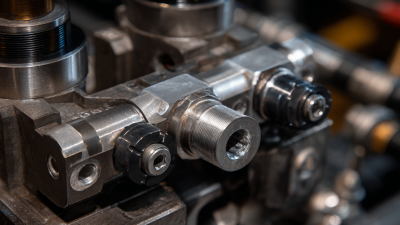

From pumps to valves, each piece plays a critical role. While many manufacturers offer a range of options, not all components deliver optimal performance. It's essential to recognize that quality can vary significantly. A mismatched component can lead to inefficiencies, increased wear, and possible system failures.

Choosing the right hydraulic components does not guarantee perfection. Challenges persist, and it can be difficult to pinpoint the best fit for specific applications. Users must stay informed about new trends and innovations. Continual reflection on performance is crucial in the pursuit of maximizing system efficiency. Striving for improvement is an ongoing journey.

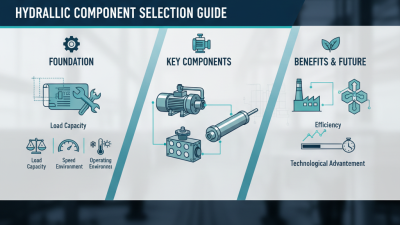

Key Features of High-Performance Hydraulic Components in 2026

In 2026, high-performance hydraulic components are expected to focus on efficiency and durability. Research indicates that advanced materials will be crucial. For example, high-strength alloys can enhance resilience and reduce wear. The right material choice can increase component lifespan by up to 30%. This aids in reducing maintenance costs.

Energy efficiency is another critical feature. According to the Hydraulics Research Institute, new designs can improve energy use by 15%. Such improvements help industries save significantly on operational expenses. Compact designs will also gain traction. They save space and weight, making installations easier and more versatile.

However, the hydraulic industry faces challenges. Not all companies adapt to new technologies swiftly. Some still rely on outdated designs, which may not meet today’s efficiency standards. There’s a learning curve involved. Companies must invest in training and updates to keep up. A focus on performance can lead to higher production rates, but the transition isn’t always smooth.

Comparison of Leading Hydraulic Component Brands for Optimal Results

When comparing leading hydraulic component brands, several factors come into play. The materials used in each component affect durability. Some brands may prioritize cost over longevity, leading to frequent replacements. This can be frustrating for operators who expect reliability.

Operational efficiency often varies between manufacturers. It's crucial to analyze the hydraulics' performance under real-world conditions. Testing different components in different settings can reveal unexpected results. You may find that the cheapest option fails more often than anticipated.

Tips: Always evaluate compatibility with existing systems. An incompatible component can derail productivity. Consider maintenance requirements as well. Some brands may require frequent servicing, adding to ongoing costs. This evaluation is essential for making informed choices.

Hydraulic efficiency is not just about selection. Monitoring and adjusting system settings contribute to performance. A well-tuned system can enhance productivity and reduce downtime. Regular maintenance can reveal potential problems early. Ignoring these can lead to costly repairs. Adjust as needed for optimal results.

2026 Best Hydraulic Components Performance Comparison

Innovative Technologies Driving Hydraulic Component Efficiency in 2026

The future of hydraulic components in 2026 hinges on innovative technologies. Recent industry reports indicate a growing trend in integrated sensing technologies. These advancements enhance performance by predicting component failures. Predictive maintenance can reduce downtime by up to 30%. This improvement boosts overall productivity and efficiency.

Another key trend is the development of lightweight materials. Use of advanced composites can reduce component weight by nearly 40%. Lighter components can lead to lower energy consumption. Industry standards suggest that energy efficiency can improve by 15% to 20% with these materials. However, the transition isn't seamless. Adapting manufacturing processes requires time and investment.

Digitalization is also transforming hydraulic systems. With IoT integration, real-time monitoring becomes possible. This shift allows for proactive adjustments and optimization. Data analytics can identify inefficiencies, but it poses a learning curve for many companies. The benefits are clear, yet implementing change can be daunting. Many organizations are still struggling to fully adapt to these new technologies. As the industry evolves, continuous engagement with these innovations will be crucial.

2026 Best Hydraulic Components for Optimal Performance

| Component Type | Material | Efficiency (%) | Temperature Resistance (°C) | Pressure Rating (bar) |

|---|---|---|---|---|

| Hydraulic Pump | Cast Iron | 95 | 80 | 350 |

| Hydraulic Cylinder | Aluminum Alloy | 90 | 100 | 300 |

| Hydraulic Valve | Brass | 92 | 90 | 250 |

| Hydraulic Filter | Stainless Steel | 88 | 120 | 200 |

| Hydraulic Hose | Rubber | 85 | 60 | 180 |

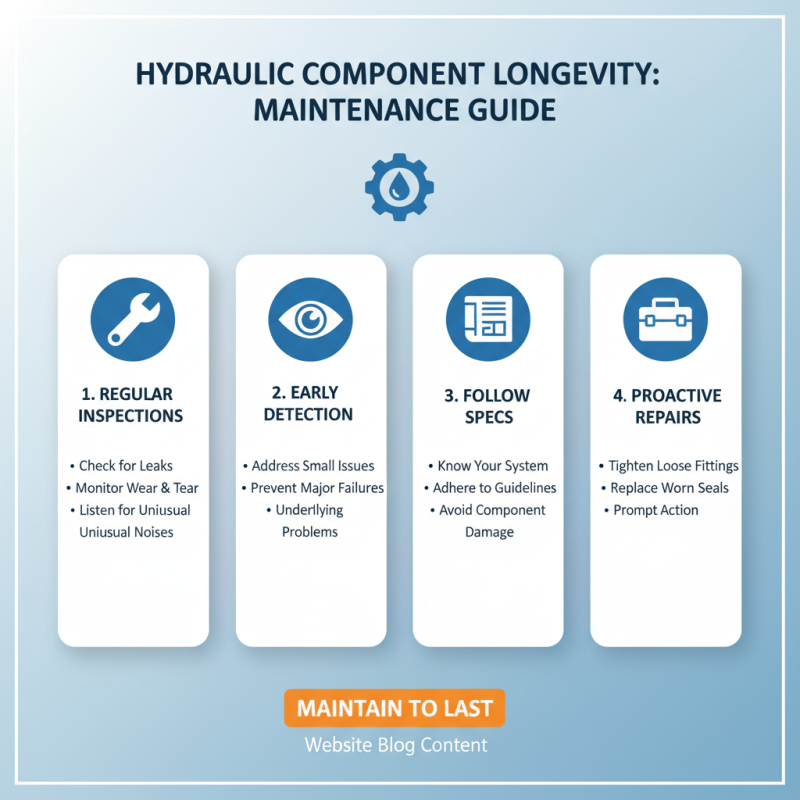

Maintenance Best Practices for Prolonging Hydraulic Component Lifespan

Proper maintenance is crucial for extending the lifespan of hydraulic components. Regular inspections can catch small issues before they become major problems. Look for signs of leaks, wear, or unusual noises. These could indicate underlying issues that need attention. Understand the specifications of your hydraulic system. Follow these specifications closely to prevent damaging components. Tighten loose fittings and replace worn seals as soon as possible.

Fluid quality plays a significant role in performance. Contaminated fluid can cause excessive wear. Regularly check the fluid for clarity and debris. Replace it when necessary to ensure optimal efficiency. Monitoring temperature is essential. Overheating can ruin seals and lead to failures. Install gauges to keep track of fluid temperatures.

Training operators is often overlooked. Even small mistakes can lead to costly repairs. Ensure that everyone understands proper operation techniques. It can save time and money in the long run. Pay attention to how components are used daily. Sometimes, it's a simple oversight that causes significant issues. Make a habit of reviewing maintenance logs. They can provide insights into recurring problems and areas for improvement.

Future Trends in Hydraulic Components for Enhanced System Performance

The hydraulic component industry is witnessing transformative trends. Innovations are essential for enhancing performance in diverse applications. The global hydraulic components market is projected to reach $60 billion by 2026, signaling a strong demand for efficiency and sustainability.

Developments in smart technology are a key focus area. Sensors embedded in hydraulic systems provide real-time data. This helps in predictive maintenance and reduces downtime. According to a recent industry report, 30% of system failures could be avoided with proactive monitoring.

Tips: Regularly review system performance metrics. This will highlight areas for improvement. Additionally, consider energy-efficient hydraulic fluids. They contribute to longer component life and reduced operational costs.

The shift towards eco-friendly components is also notable. Companies are exploring biodegradable oils. This move aligns with environmental regulations and enhances corporate responsibility. However, some decisions may lead to higher initial costs. Balancing performance and sustainability is not easy. Each choice requires careful consideration of long-term benefits versus short-term expenses.

Related Posts

-

How to Choose the Right Hydraulic Equipment for Your Needs?

-

How to Choose the Right Hydraulic Components for Your Applications

-

Top 10 Hydraulic Equipment You Need for Your Business Success

-

Understanding the Power Behind Fluid Power Hydraulics in Everyday Machines

-

Understanding the Essential Role of Hydraulic Parts in Modern Machinery

-

Top 10 Essential Hydraulic System Components for Optimal Performance

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us