How to Choose Between Pneumatic and Hydraulic Systems?

In the world of machinery, the debate between pneumatic and hydraulic systems is ongoing. Dr. Samuel Reed, an acclaimed expert in pneumatic hydraulic technologies, once stated, "Choosing the right system is crucial for efficiency." This highlights how pivotal this decision can be for engineers and manufacturers alike.

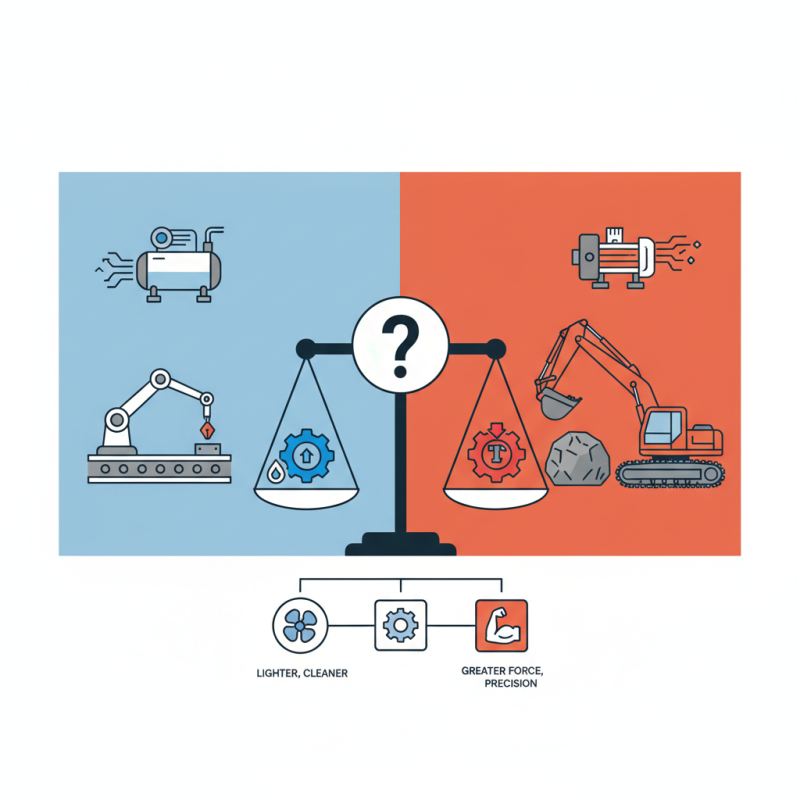

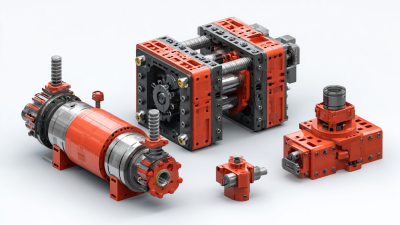

Pneumatic systems use compressed air, while hydraulic systems rely on fluid pressure. Each has unique advantages and disadvantages. For instance, pneumatic systems are typically lighter and cleaner, suitable for applications like assembly lines. Conversely, hydraulic systems offer greater force and precision, making them ideal for heavy lifting tasks.

When selecting between these systems, consider the specific requirements of your project. What materials will be moved? How much force is needed? These questions can reveal flaws in initial choices. Rushing into a decision can lead to inefficiencies and costs. Thus, careful evaluation is paramount in the pneumatic hydraulic selection process.

Pneumatic Systems: Overview and Key Applications in Various Industries

Pneumatic systems play a vital role across various industries. These systems use compressed air to perform tasks, and they are known for their speed and efficiency. From automotive factories to food processing plants, pneumatic tools like drills and lifts enhance productivity. They are often preferred for their cleaner operation, as they do not use oils or fluids.

In sectors such as construction and manufacturing, pneumatic systems offer flexibility. They can reach tight spaces and operate in extreme conditions. Yet, there are weaknesses to consider. Pneumatic systems can lose pressure, affecting performance. This dependency on air availability needs careful planning. Over time, components may wear out, leading to increased maintenance costs.

While many embrace their advantages, not everyone may appreciate the limitations. Noise levels can be significant in a work environment. Workers may find such conditions uncomfortable. Evaluation of the workspace and staff needs is crucial when choosing pneumatic systems. Understanding both strengths and weaknesses can lead to better decisions.

Comparison of Pneumatic and Hydraulic Systems

| Feature | Pneumatic Systems | Hydraulic Systems |

|---|---|---|

| Medium Used | Compressed Air | Hydraulic Fluid |

| Force Output | Low to Moderate | High |

| Speed | Fast | Slower |

| Cost | Generally Lower | Generally Higher |

| Applications | Assembly Lines, Packaging, Automation | Construction, Manufacturing, Machinery |

| Maintenance | Lower Complexity | Higher Complexity |

Hydraulic Systems: Understanding Their Functionality and Advantages

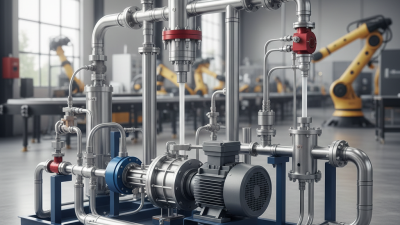

Hydraulic systems operate on the principle of fluid mechanics. They use pressurized fluid to transmit power, making them powerful tools in various industries. According to the International Fluid Power Society, hydraulic systems can generate forces that exceed those of pneumatic systems by 10 to 1. This advantage makes them suitable for heavy-load applications. However, they also come with disadvantages.

One major drawback is the complexity of maintenance. Leaks can occur, leading to fluid loss and environmental concerns. A report from the Fluid Power Journal highlights that nearly 30% of hydraulic systems experience leaks annually. Additionally, hydraulic fluid can be hazardous, requiring careful handling and disposal. The system's reliance on components like pumps and valves also raises concerns about wear and tear over time.

Despite these challenges, hydraulic systems offer advantages that are hard to ignore. They provide precise control and are capable of high lifting capacities. A study from the American Society of Mechanical Engineers found that hydraulic lifts can handle weights up to 50 tons or more. This capability is invaluable in construction and manufacturing. Thus, while hydraulic systems are powerful, potential users must thoroughly evaluate their maintenance needs and environmental impact.

Comparative Analysis: Efficiency, Cost, and Maintenance of Both Systems

When choosing between pneumatic and hydraulic systems, efficiency plays a significant role. Pneumatic systems often excel in speed. They can deliver high power with minimal latency. However, their efficiency can drop when compressed air leaks. This can lead to increased operational costs. In contrast, hydraulic systems offer better energy efficiency for heavier workloads. They use incompressible fluids, which provide consistent power transmission. But, they can be slower to react in some applications.

Cost is another important factor. Pneumatic systems might appear cheaper upfront. Equipment and installation costs are generally lower. Yet, ongoing maintenance can add up. Air compressors need regular checks. Leakage issues can also lead to unexpected expenses. Hydraulics typically have higher initial costs, but they can be cost-effective over time. They often require less maintenance, especially for critical operations.

Maintenance complexity can vary significantly between the two systems. Pneumatics may not need as intensive maintenance, but filters must be monitored. Hydraulic systems, while generally robust, require careful monitoring of fluid levels. Leaks in hydraulic systems can become costly if not addressed promptly. Both systems have strengths and weaknesses, which makes the decision more complex. Reflecting on these aspects is essential for making the right choice.

Comparative Analysis of Pneumatic vs Hydraulic Systems

Key Factors to Consider When Choosing Between Pneumatic and Hydraulic Systems

When choosing between pneumatic and hydraulic systems, several key factors come into play. One important aspect is the application environment. Pneumatic systems are ideal for clean, dry workplaces. They are less sensitive to moisture. In contrast, hydraulic systems can handle heavy loads and are suitable for high-pressure environments.

Consider the energy source as well. Pneumatic systems use compressed air, which is easy to distribute and control. However, the efficiency can be lower, especially at larger scales. Hydraulics utilize fluid, often providing greater force and efficiency. But, this comes with a complex setup and maintenance challenges.

**Tip:** Evaluate your specific use case before making a decision. Understanding operational needs is essential. For smaller tasks, pneumatics might suffice. Larger projects often benefit from hydraulic power.

Another factor to think about is safety and maintenance. Pneumatic systems are generally safer. They pose less risk of leaks and spills. However, the noise factor can be bothersome. On the other hand, hydraulic systems can handle larger forces but require more maintenance. Leaks can lead to hazardous conditions.

**Tip:** Regular checks can help prevent major issues. Look for signs of wear and tear in hydraulic systems. In pneumatic systems, monitor air quality and pressure levels.

Industry Trends: Future Developments in Pneumatic and Hydraulic Technologies

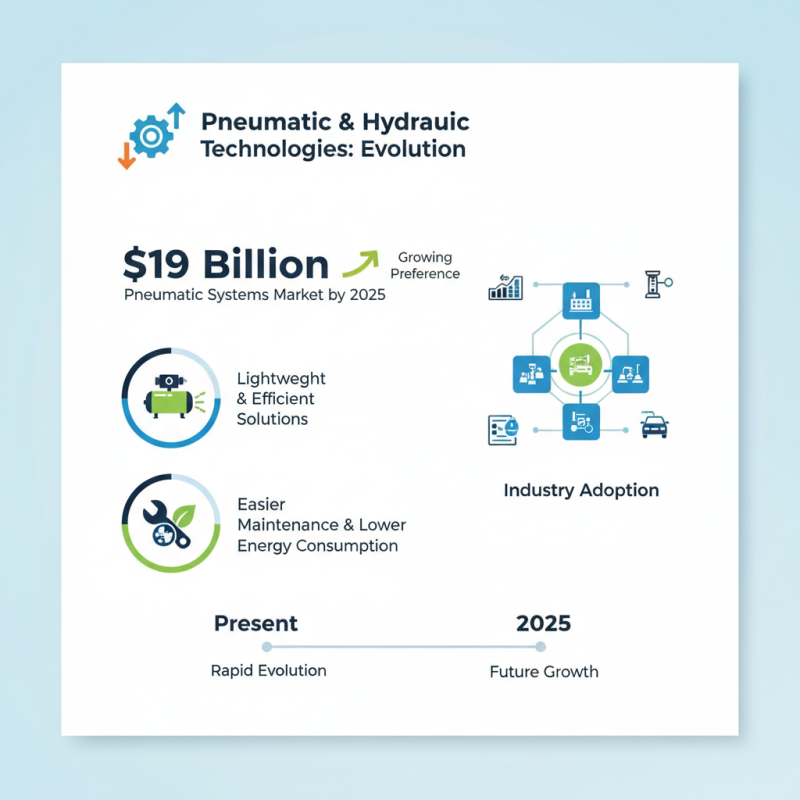

The landscape of pneumatic and hydraulic technologies is evolving rapidly. Recent industry reports show that the pneumatic systems market is projected to reach $19 billion by 2025. This highlights the growing preference for lightweight and efficient solutions in various applications. Industries are increasingly drawn to pneumatic systems due to their easier maintenance and lower energy consumption.

However, hydraulic systems continue to play a critical role, particularly in heavy machinery. A report indicates that the hydraulic market will also experience growth, expected to surpass $19 billion by 2026. Hydraulics excel in providing higher power output in compact sizes. Still, their complexity can raise maintenance costs and technical challenges.

As industries explore both technologies, they must weigh these pros and cons carefully. Emerging trends indicate a potential hybrid approach could provide a solution. For instance, combining pneumatic systems' energy efficiency with hydraulic systems' power could redefine operational standards. However, such integrations still require thorough evaluation of compatibility and long-term performance.

Related Posts

-

The Best 10 Advantages of Pneumatic Hydraulic Systems for Your Business

-

Essential Pneumatic Hydraulic Maintenance Checklist for Optimal Performance

-

2025 Top Hydraulic Equipment Trends You Need to Know for Your Business

-

How to Optimize Pneumatic Hydraulic Systems for Enhanced Performance

-

Understanding Common Issues with Hydraulic Pumps and Motors in Industrial Applications

-

Unlocking the Future of Machinery: Innovative Trends in Hydraulic Parts for Enhanced Efficiency

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us