2025 How to Choose Between Pneumatic and Hydraulic Systems for Your Projects

In the ever-evolving landscape of industrial automation, the choice between pneumatic and hydraulic systems can be pivotal for the success of a project. Industry expert Dr. Emily Thompson, a leading authority in fluid power technologies, once stated, "The decision between pneumatic and hydraulic systems should be driven by the specific requirements of your application, as each offers distinct advantages and trade-offs." With various factors to consider, including efficiency, force output, and operational environments, engineers must navigate their options carefully.

Pneumatic and hydraulic systems both offer unique benefits tailored to different applications. Pneumatics excels in speed and responsiveness, making it ideal for tasks requiring quick, repeated motions. On the other hand, hydraulics is renowned for its ability to generate tremendous force, which is essential in heavy lifting and high-pressure environments. As industries push for increased productivity and innovation, understanding the nuances of these two systems becomes increasingly important for professionals tasked with optimizing performance.

In summary, selecting between pneumatic and hydraulic systems is not merely a technical choice, but rather a strategic decision that can significantly impact project outcomes. By weighing the specific needs and conditions of their operations, engineers can harness the power of pneumatic and hydraulic technologies to achieve remarkable efficiencies and effectiveness in their projects.

Understanding Pneumatic Systems: Principles and Applications

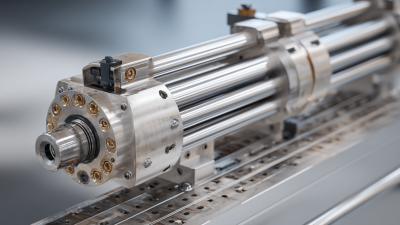

Pneumatic systems utilize compressed air to transmit energy, making them a popular choice in various industrial applications. The fundamental principle behind these systems is based on the efficient conversion of air pressure into mechanical work. By employing actuators like cylinders and valves, pneumatic systems can perform tasks such as lifting, moving, and positioning heavy loads. The lightweight nature of these components also allows for quick installation and maintenance, further enhancing their appeal in dynamic work environments.

Applications of pneumatic systems are vast and diverse. They are commonly used in manufacturing processes, such as assembly lines, packaging, and material handling. These systems excel in environments where speed and precision are critical, as they can achieve rapid cycle times without overheating. Additionally, since air is readily available and does not pose the same environmental or safety risks as hydraulic fluids, pneumatic systems are often favored in applications where cleanliness and safety are paramount. Understanding these principles enables engineers and project managers to effectively assess the suitability of pneumatic systems for their specific needs.

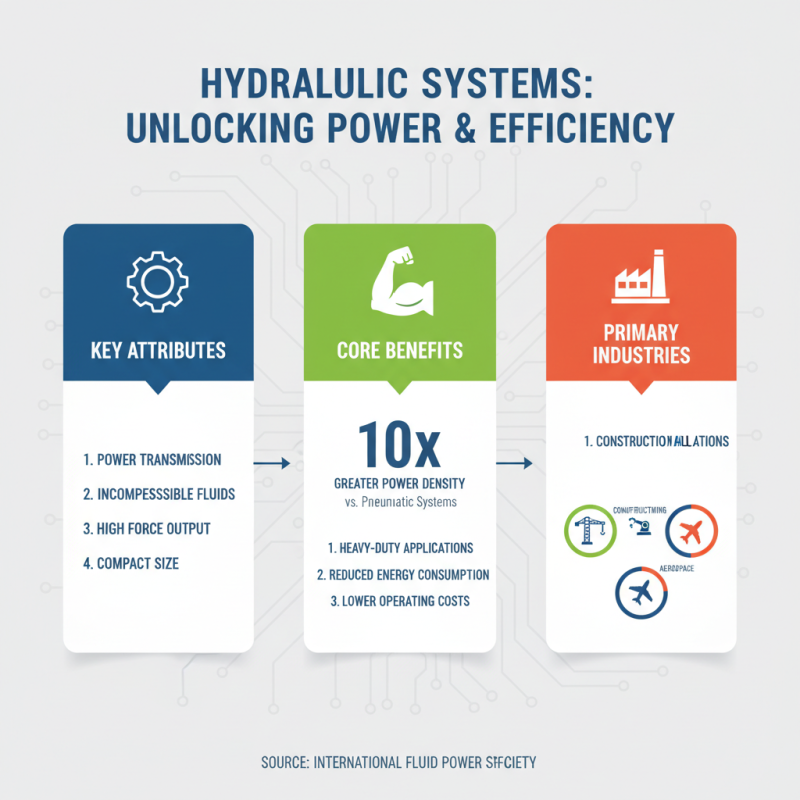

Exploring Hydraulic Systems: Key Features and Benefits

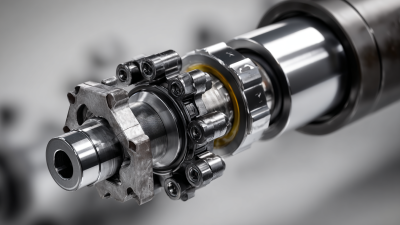

Hydraulic systems are essential in various industries due to their unique features and numerous benefits. One of the key attributes is their ability to transmit power efficiently through the use of incompressible fluids, which allows for high force output with minimal physical size. According to the International Fluid Power Society, hydraulic systems can deliver power densities up to 10 times greater than pneumatic systems, making them particularly suitable for heavy-duty applications in construction, manufacturing, and aerospace. This efficiency translates into reduced energy consumption and lower operating costs, which are vital considerations for any project budget.

Another significant advantage of hydraulic systems is their precise control and responsiveness. The capability for fine adjustments allows for greater accuracy in tasks such as positioning and moving heavy loads. A recent report by the Hydraulic Institute indicates that users experience an increase in operational efficiency by up to 25% when utilizing advanced hydraulic control systems. Additionally, hydraulic machinery often boasts better durability and longevity under demanding conditions, reinforcing its choice as a reliable solution for high-stakes projects. These features make hydraulic systems a compelling option for engineers and project managers aiming to optimize performance and cost-effectiveness in their operations.

Comparative Analysis: Pneumatic vs. Hydraulic Systems

When choosing between pneumatic and hydraulic systems for projects, a comparative analysis reveals key differences that can significantly influence performance and application. Pneumatic systems utilize compressed air to transmit power, offering advantages such as lighter weight, faster response times, and fewer maintenance requirements. They excel in environments where speed and cleanliness are paramount, making them ideal for automotive assembly lines and electronic component handling. Additionally, the inherent safety of pneumatic systems, due to the non-flammable nature of air, is a critical consideration in industries where fire hazards are a concern.

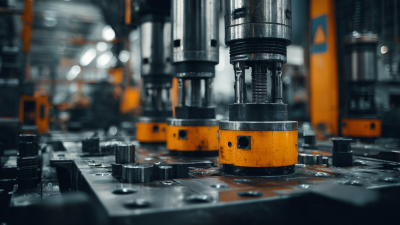

Contrastingly, hydraulic systems employ pressurized fluids to generate movement and force. This method delivers greater power and efficiency for heavy-duty applications, making it suitable for tasks that require substantial force, such as in construction equipment or manufacturing machinery. Hydraulic systems can also maintain consistent pressure, providing better control in operations demanding precision. However, they often come with added complexity in terms of fluid management and potential leakage issues, necessitating more rigorous maintenance protocols. Ultimately, the choice between these systems should be dictated by the specific needs of the project, including factors like required force, speed, and environmental considerations.

Comparative Analysis of Pneumatic vs. Hydraulic Systems

Factors Influencing System Selection for Your Project

When choosing between pneumatic and hydraulic systems for your projects, several factors come into play that can significantly influence your decision. One of the primary considerations is the type of application you are working on. Pneumatic systems, which utilize compressed air, are often suited for applications that require rapid movement and lighter loads. Conversely, hydraulic systems, which rely on pressurized fluid, are ideal for tasks demanding high force and precision, such as heavy lifting and complex machinery operations.

Another critical factor is the operating environment. Pneumatic systems perform well in environments that require cleanliness, as they do not produce any hydraulic fluid leaks that can contaminate the area. Furthermore, pneumatic systems generally operate at lower pressures and are less susceptible to temperature fluctuations that can affect hydraulic systems. This distinction can make pneumatic systems preferable in food processing or pharmaceutical industries. On the other hand, if the project involves outdoor applications or extreme conditions where environmental factors could impact operation, hydraulic systems may offer the robustness needed to withstand such challenges.

Practical Considerations: Cost, Maintenance, and Efficiency

When selecting between pneumatic and hydraulic systems for your projects, several practical considerations must come into play, particularly cost, maintenance, and efficiency. Pneumatic systems typically have lower initial costs and can be easier to install. They utilize compressed air which is often readily available in many industrial settings, making them an attractive option for smaller projects or applications where extensive power isn't required. However, while the setup might be economical, the operational costs can add up, especially if the systems require a constant supply of compressed air.

On the other hand, hydraulic systems tend to have a higher upfront investment due to the complexity of their components and the need for a more robust infrastructure. However, they offer significant advantages in terms of efficiency and power output for heavy-duty applications. Hydraulic systems can handle larger loads and provide a smoother operation with greater control over speed and force. This capability can lead to lower energy costs in the long run, making them a more economical choice for demanding tasks, despite their initial expense. Moreover, maintenance is another critical factor; pneumatic systems may require more frequent checks for leaks and other air-related inefficiencies, while hydraulic systems, although initially more complex, often lead to less downtime when properly maintained.

Related Posts

-

How to Optimize Pneumatic Hydraulic Systems for Enhanced Performance

-

10 Essential Tips for Mastering Pneumatic and Hydraulic Systems

-

Essential Pneumatic Hydraulic Maintenance Checklist for Optimal Performance

-

Pneumatic Hydraulics Versus Traditional Hydraulics A Comprehensive Comparison of Efficiency and Performance

-

Why Understanding Pneumatic and Hydraulic Systems is Essential for Modern Industries

-

Understanding the Essential Role of Hydraulic Parts in Modern Machinery

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us