How to Choose the Right Hydraulic Equipment for Your Needs?

Choosing the right hydraulic equipment can be a complex task. It requires careful consideration and expert advice. According to John Smith, a hydraulic equipment specialist, “Selecting the right tools can make or break a project.” His words highlight the importance of making informed decisions.

Hydraulic equipment varies widely in type and application. Different jobs require specific features and capacities. It can be overwhelming to navigate the options available. Factors like pressure, flow rate, and type of operation come into play. A wrong choice may lead to inefficiency or even equipment failure.

At times, users encounter dilemmas when matching needs with available equipment. Additionally, financial constraints can further complicate decision-making. Reflecting on these aspects is vital. Ultimately, understanding your own requirements and consulting with professionals can lead to better choices in the long run.

Understanding Your Hydraulic Equipment Requirements

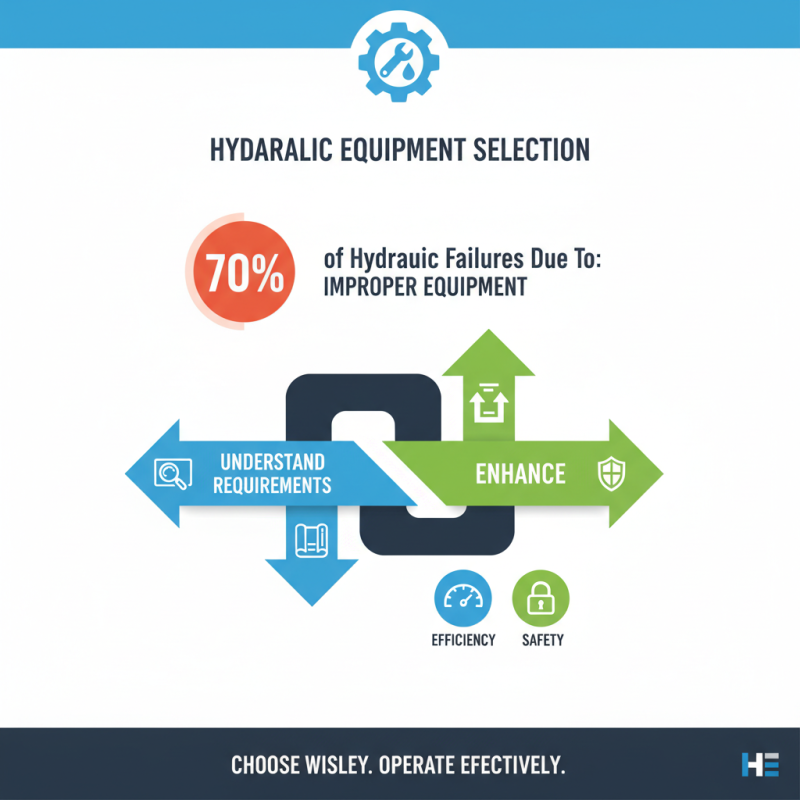

Understanding your hydraulic equipment requirements is crucial for effective operation. The right choice can enhance efficiency and safety. According to a recent industry report, 70% of hydraulic system failures are due to improper selection of equipment. This highlights the significance of understanding specific needs before making a purchase.

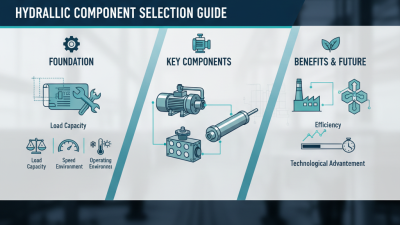

Begin by assessing the application. What will the equipment be used for? Factors like load capacity, pressure ratings, and flow rates are vital. A mismatch can result in reduced performance or even catastrophic failures. For instance, a construction site might require equipment that withstands extreme conditions, while a manufacturing plant may prioritize precision and control.

In addition, consider the environmental factors. Does your application involve temperature extremes or exposure to hazardous substances? A study indicates that 65% of users overlook these details. Ignoring these can lead to premature wear or even equipment breakdown. Proper evaluation of your requirements can lead to better decisions and improved operational longevity.

Identifying Key Applications for Hydraulic Systems

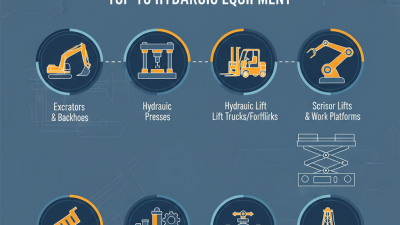

When selecting hydraulic systems, identifying key applications is crucial. Many sectors rely on hydraulic equipment, including construction, manufacturing, and agriculture. According to a recent industry report, the hydraulic equipment market is projected to grow by 4.5% annually. This growth underscores the importance of choosing the right system for specific needs.

In construction, hydraulic systems power excavators and loaders. Understanding the required force and precision is essential for optimal performance. In agriculture, hydraulic equipment operates tractors and harvesters. Here, efficiency is key. A miscalculation in hydraulic pressure could lead to crop loss. Many operators neglect maintenance, which can result in costly downtime.

Hydraulic systems also play a critical role in manufacturing. They enable automation in assembly lines, enhancing productivity. Yet, not all processes are suitable for hydraulic applications. Some operations may demand more flexibility. This confusion can hinder decisions. Investing time in assessing application needs is vital. Data shows that improper selection can lead to 20-30% inefficiencies. Being aware of these factors can guide better choices.

Evaluating Hydraulic Equipment Types and Their Functions

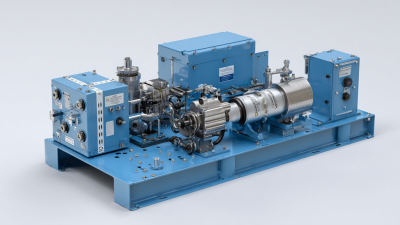

When selecting hydraulic equipment, understanding different types is crucial. Numerous options exist, each serving specific functions. For example, hydraulic cylinders are essential for lifting and pushing tasks. Their power and versatility make them popular in various industries. These units convert hydraulic energy into mechanical work, enabling impressive force generation.

Another common option includes hydraulic pumps. They create fluid flow essential for system functionality. There are gear, vane, and piston pumps. Each type has its strengths. The choice of pump affects efficiency and performance. It's vital to consider the specific application and required pressure ratings.

Not all equipment will meet your needs perfectly. You might find that a chosen type underperforms in your scenario. Adjusting your selection can lead to better outcomes. Testing equipment under real conditions helps identify limitations. Look for equipment that balances performance with reliability. Be prepared to revisit your choices as your project evolves.

Assessing Compatibility with Existing Systems and Components

When choosing hydraulic equipment, compatibility with existing systems is crucial. Think about the specifications of your current setup. Check pressure ratings, flow rates, and connector types. This ensures seamless integration. Mismatches can lead to inefficiencies or even failures. It's vital to consider the age of your systems. Older components may not work well with modern hydraulic machines.

Tips: Always measure your current hydraulic lines. This will help avoid costly modifications. Test compatibility using small-scale models before committing to larger installations. Doing so can reveal hidden issues that need attention.

Another aspect to reflect on is the environment where the equipment will be used. Consider temperature variations and potential contamination. These factors can affect performance and longevity. If you're unsure, consult with professionals who can provide tailored advice. They may highlight incompatibilities you hadn’t considered. Remember, overlooking small details can lead to big problems down the line.

Hydraulic Equipment Compatibility Assessment

This bar chart illustrates the compatibility scores of various hydraulic equipment components that are essential for optimal system performance. Higher scores indicate better compatibility with existing systems.

Budgeting for Hydraulic Equipment Acquisition and Maintenance

When budgeting for hydraulic equipment, consider both acquisition and maintenance costs. Initial purchase prices can vary significantly. It's wise to research different suppliers and compare options. Remember, quality often affects the price. Cheaper options might cost more in the long run due to repairs.

Tips for budgeting include allocating funds for unexpected expenses. Hydraulic systems can fail; finding parts may take time. Set aside at least 10% of your budget for maintenance. Regular servicing prevents breakdowns and extends equipment life.

Don't overlook training costs. Operating hydraulic equipment safely is crucial. If your team is not adequately trained, it can lead to misuse and costly mistakes. Investing in proper training pays off with efficient operation and fewer accidents. Reflect on your current equipment's reliability. Are maintenance costs increasing? If so, it may be time to consider alternatives.

How to Choose the Right Hydraulic Equipment for Your Needs? - Budgeting for Hydraulic Equipment Acquisition and Maintenance

| Equipment Type | Average Acquisition Cost | Maintenance Cost (Annual) | Typical Lifespan (Years) | Best Use Cases |

|---|---|---|---|---|

| Hydraulic Press | $15,000 | $1,200 | 15 | Metal forming, Research labs |

| Hydraulic Excavator | $80,000 | $4,000 | 10 | Construction, Demolition |

| Hydraulic Pump | $5,000 | $500 | 7 | Agricultural, Industrial |

| Hydraulic Cylinder | $3,000 | $300 | 10 | Machinery, Elevators |

| Hydraulic Forklift | $45,000 | $2,000 | 8 | Warehousing, Logistics |

Related Posts

-

How to Choose the Right Hydraulic Components for Your Applications

-

Top 10 Hydraulic Equipment You Need for Your Business Success

-

How to Choose Between Pneumatic and Hydraulic Systems for Your Projects

-

Understanding the Power Behind Fluid Power Hydraulics in Everyday Machines

-

2025 Top Hydraulic Equipment Trends You Need to Know for Your Business

-

Top 10 Essential Hydraulic System Components for Optimal Performance

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us