How to Choose the Right Hydraulic Fittings for Your Needs?

Choosing the right hydraulic fittings is crucial for system performance and safety. In the hydraulic industry, proper fitting selection impacts fluid flow and pressure management. A report by Research and Markets states that the global hydraulic fittings market is expected to reach $5.82 billion by 2027. This emphasizes the importance of quality and reliability in hydraulic components.

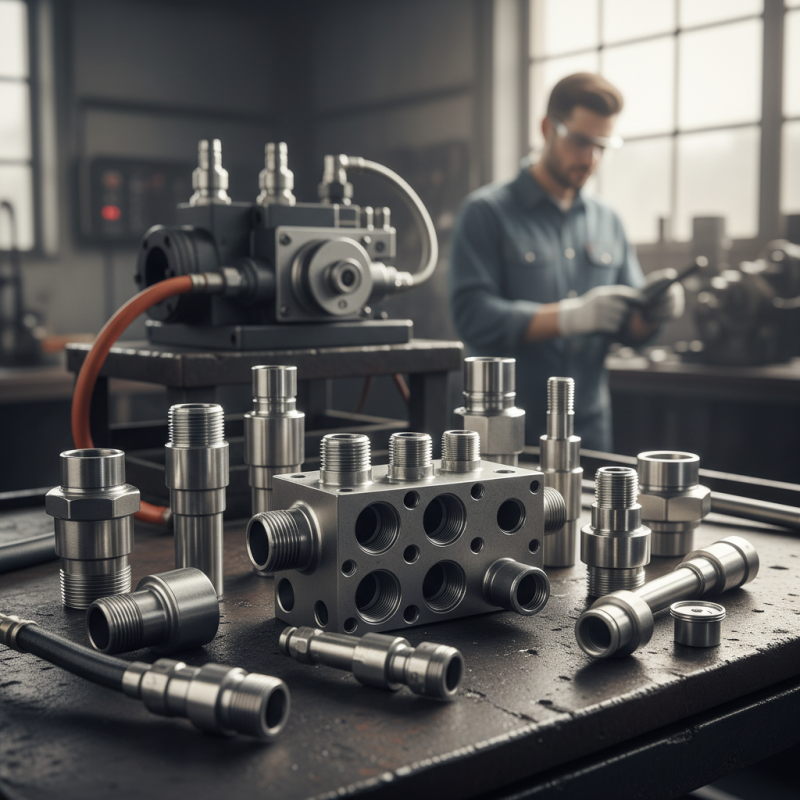

Expert John Smith, a hydraulic systems engineer, once stated, "Selecting the correct hydraulic fittings can define the efficiency of any hydraulic system." His insight highlights the consequences of poor choices. The wrong fitting can lead to leaks, increased downtime, and costly repairs. Hydraulic fittings come in various materials, sizes, and configurations, making it essential to understand specific application requirements.

Different industries, such as automotive and aerospace, have unique needs. Each situation demands careful evaluation of factors like pressure ratings and temperature ranges. Often, organizations overlook these details. The consequences can be severe. Effective selection of hydraulic fittings not only enhances system longevity but also reduces safety risks. Understanding these aspects is vital for project success.

Understanding Hydraulic Fittings and Their Types

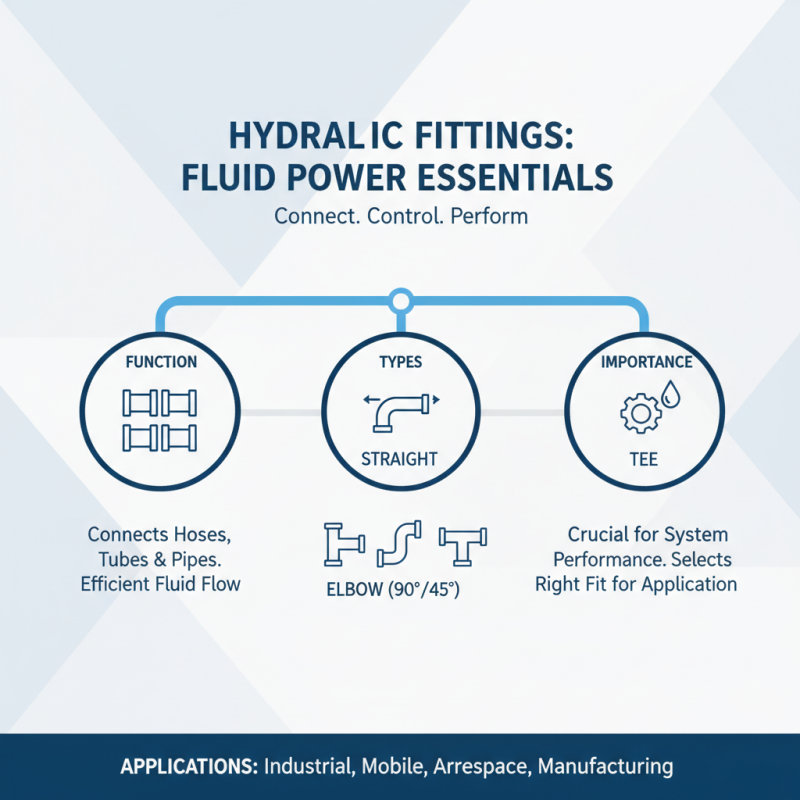

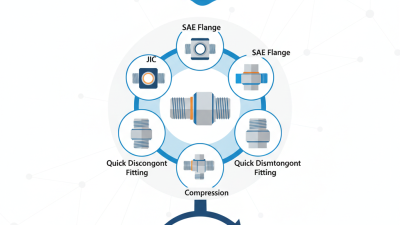

Hydraulic fittings are essential components in fluid power systems. They connect hoses, tubes, and pipes, ensuring that the hydraulic fluid flows efficiently. Understanding the different types of hydraulic fittings is crucial for selecting the right ones for your needs. For instance, there are straight fittings, elbow fittings, and tee fittings. Each type serves a unique purpose in various applications.

According to a report by Research and Markets, the hydraulic fittings market is projected to grow significantly, with an estimated CAGR of 5.2% from 2021 to 2026. Such growth indicates the increasing reliance on hydraulic systems across industries. However, the choice of fittings often gets overlooked. Selection is not just about compatibility; it also involves considering pressure ratings. Fittings must withstand the system's maximum pressure. If a fitting fails, it could lead to system malfunctions.

Many users underestimate the importance of material selection. Common materials include steel and brass. Each has its advantages and disadvantages. Steel is durable but can corrode, while brass offers good resistance but may be more expensive. Ignoring these details can result in frequent replacements. A small oversight in choosing the right fitting can lead to large repercussions, such as costly downtime or repairs.

Identifying Your Specific Hydraulic System Requirements

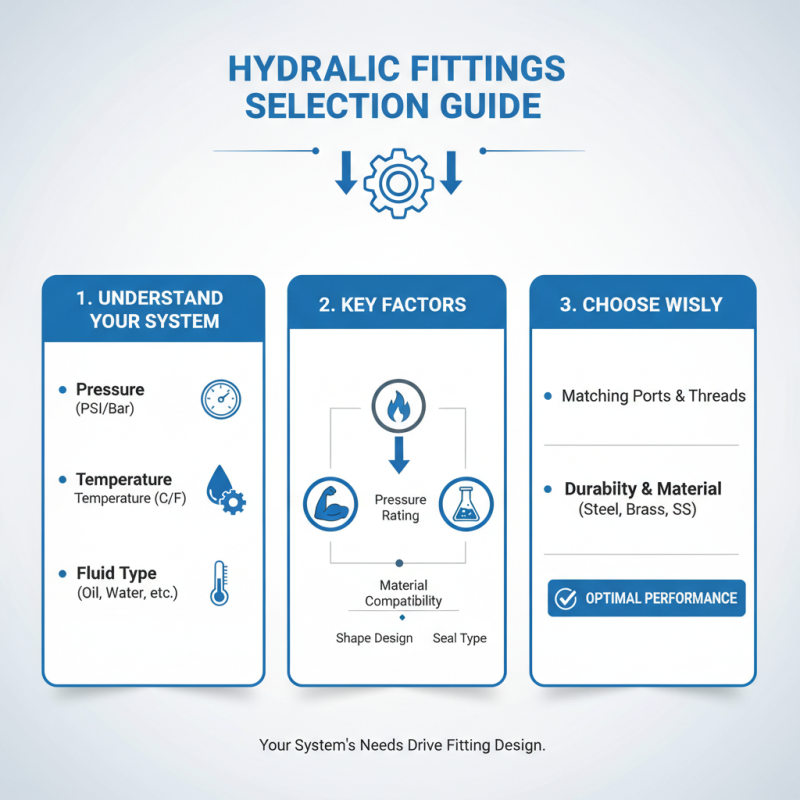

Choosing the right hydraulic fittings starts with understanding your hydraulic system requirements. Each system has unique characteristics that dictate its needs. Consider factors like pressure, temperature, and fluid type. These elements shape the design and functionality of your fittings.

Tips for identifying requirements: Analyze your system's specifications. Are you dealing with high pressure? Ensure your fittings can withstand the stress. Check the fluid compatibility too. Not all materials work well with every fluid. A mismatch can lead to failures.

Look at the connection type. Do you need threaded, flanged, or quick-connect fittings? Assess your space constraints; some fittings may not fit where you need them. Be open to making adjustments. Sometimes, what seems ideal on paper may not work in practice. Experimentation is key.

Key Factors to Consider When Selecting Hydraulic Fittings

Choosing the right hydraulic fittings is essential for optimal performance. When assessing options, begin with the fitting type. Different systems require various types. Some may use JIC fittings, while others require NPT or BSP. Understanding your system's requirements is crucial.

Material selection is another key factor. Common materials include stainless steel and brass. Stainless steel fittings are durable and resistant to corrosion. Brass fittings are often more affordable but may not perform as well in harsh environments. Consider the operating conditions, such as pressure and temperature.

Don't overlook size and thread type. Mismatched sizes can lead to leaks and inefficient system performance. Measure the existing components carefully. Additionally, ensuring the thread type matches is vital for a secure connection. This detail can be an easy overlook. It's worth double-checking to prevent future headaches.

| Parameter | Description | Importance |

|---|---|---|

| Size | Ensure fittings match the size of hoses and pipes. | Critical for preventing leaks and ensuring compatibility. |

| Material | Common materials include steel, stainless steel, and aluminum. | Affects durability and resistance to corrosion. |

| Pressure Rating | Fittings should match or exceed system pressure requirements. | Essential for safety and system reliability. |

| Thread Type | Common thread types include NPT, BSP, and JIC. | Ensures secure connections without leaks. |

| Operating Environment | Consider temperature and exposure to chemicals. | Impacts material choice and fitting longevity. |

| Application Type | Different applications may require specific fitting designs. | Coordinates with system requirements effectively. |

Common Materials Used in Hydraulic Fittings and Their Benefits

When selecting hydraulic fittings, the material plays a crucial role. Commonly used materials include steel, stainless steel, brass, and various plastics. Each material has unique benefits that affect performance and longevity.

Steel fittings are known for their strength and durability. They can withstand high pressures, making them ideal for heavy-duty applications. Stainless steel, on the other hand, offers excellent corrosion resistance, which is vital in harsh environments.

Brass fittings are often preferred for their reliability and ease of installation. They are lightweight and resistant to rust, suitable for various hydraulic systems. According to industry reports, around 30% of failures in hydraulic systems can be traced back to inadequate fittings. So, choosing the right material is essential to avoid costly downtime.

Tip: Always consider the working environment when selecting materials. If the application involves exposure to moisture or chemicals, opt for corrosion-resistant options. It's also essential to understand the pressure requirements of your system.

Plastic fittings can be a budget-friendly alternative, especially in low-pressure systems. However, they may not be suitable for all applications. While they are lightweight and resistant to rust, they have limitations in handling high pressures. Assess the specific needs of your hydraulic system before making a choice.

Ensuring Compatibility with Existing Equipment and Standards

When selecting hydraulic fittings, ensuring compatibility with existing equipment is crucial. Many operators overlook this vital step. Using fittings that do not match can lead to leaks or system failures. It is essential to check the specifications of your current setup before making a purchase.

Tips: Always verify the pressure ratings of your fittings. Mismatches can cause dangerous situations. Double-check the size and thread type too. A common mistake is assuming all fittings are interchangeable.

Standards vary by industry. Research the relevant regulations governing hydraulic systems. This knowledge can save time and avoid costly mistakes. It's easy to feel overwhelmed with choices. Take your time to assess your options carefully.

Tips: Don't rush your decisions. Consult with peers or specialists if needed. Sharing experiences can provide valuable insights that can guide your selection. Remember, each choice impacts the overall performance of your hydraulic system.

Hydraulic Fittings Compatibility Analysis

This chart depicts the compatibility ratings of various hydraulic fittings materials. The compatibility rating ranges from 1 to 10, indicating how well each material fits with existing hydraulic systems. Steel and Stainless Steel offer the best compatibility, making them preferable choices for critical applications.

Related Posts

-

2026 Best Hydraulic Components for Optimal Performance?

-

Top 5 Hydraulic Fittings to Enhance Your Equipment Performance?

-

5 Essential Tips for Choosing the Right Hydraulic Pump Motor for Your Industrial Needs

-

7 Best Hydraulic Motors for Efficient Energy Solutions in 2024

-

Ultimate Guide to Selecting the Right Hydraulic Hose Fittings for Your Project

-

Understanding the Essential Role of Hydraulic Power Packs in Modern Machinery

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us