How to Choose the Right Hydraulic Parts for Your Equipment

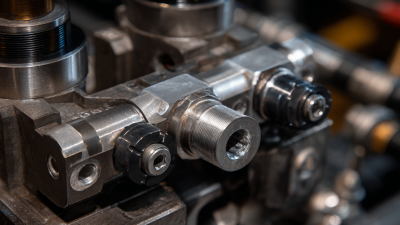

Choosing the right hydraulic parts for your equipment can be challenging. Many factors influence this decision. Understanding the specific needs of your machine is crucial.

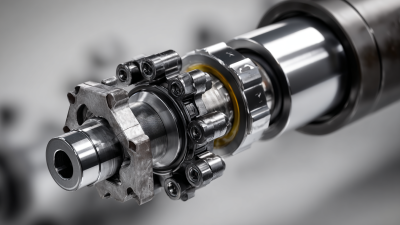

Hydraulic parts play a vital role in ensuring optimal performance. They contribute to efficiency and reliability. Each component must be compatible and high-quality to prevent failures. Often, a single overlooked part can lead to significant downtime.

Consider your equipment's specifications carefully. Match your components to their operational requirements. Knowing the differences in types and materials will help you make informed choices. Be prepared for trial and error. Sometimes, it takes several attempts to find the perfect fit. Reflect on your past experiences and use them as a guide.

Understanding the Importance of Choosing Quality Hydraulic Parts

Choosing quality hydraulic parts is crucial for any equipment. High-quality components ensure reliability and efficiency. They reduce the risk of breakdowns and extend the lifespan of your machinery. When the right parts are selected, performance improves significantly. It's not just about functionality; it’s about safety, too.

Many overlook the importance of quality. Inexpensive parts might be tempting. However, they often lead to higher long-term costs. A single failure can cause severe downtime. This might disrupt operations or compromise safety. Investing in quality helps prevent these issues. It is wise to thoroughly assess your options. Research is key before making a decision.

People sometimes settle for what is available. This can result in regrettable choices. Quality assurance should never be an afterthought. Choosing the right parts requires careful consideration. Think about your equipment’s specific needs. Each component plays a vital role. Reflect on your decisions to ensure optimal performance. Your equipment deserves the best.

Hydraulic Parts Quality vs. Equipment Efficiency

This chart illustrates the relationship between the quality of hydraulic parts and the efficiency of equipment. As the quality improves from low to high, the equipment efficiency increases significantly, highlighting the importance of selecting quality hydraulic components for optimal performance.

Identifying the Specific Hydraulic Components Required for Your Equipment

Choosing the right hydraulic parts can be daunting. Understanding your equipment's needs is the first step. Take note of the specific components your machinery requires. This could be pumps, valves, or cylinders. Each piece has a unique function. Identifying these parts will help in sourcing the correct options.

Tips: Always consult your equipment manual. This document outlines necessary specifications. If it’s missing, reach out to a dealer for guidance.

It is important to assess compatibility. Measure dimensions and force requirements. Not all parts fit every machine. Misalignment can lead to failures. Document your findings. Learn from previous experiences to prevent mistakes. Sometimes, the part you choose may seem right, but it doesn't perform well in practice.

Tips: Keep a record of your hydraulic system's performance. This can help in future purchases. If a component fails, analyze why it happened. Understanding past errors can guide better decisions next time.

Factors to Consider When Selecting Hydraulic Parts for Optimal Performance

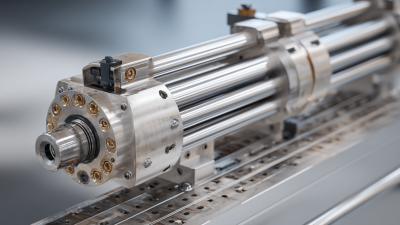

When selecting hydraulic parts for your equipment, consider compatibility as a key factor. The right parts enhance performance and longevity. According to industry research, nearly 30% of equipment failures stem from using mismatched components. Proper sizing and matching specifications can prevent costly breakdowns. Ignoring this can lead to inefficiencies.

Material choice is crucial as well. Systems often encounter harsh conditions. If parts fail due to corrosion or wear, operational downtime increases. Recent studies indicate that high-quality materials can reduce maintenance costs by up to 25%. Buying cheap components may save money upfront but can lead to larger expenses down the line.

Also, pay attention to system pressure and flow rates. Hydraulic systems operate under specific conditions. Using parts that can’t handle the required pressure affects performance. Surprisingly, 40% of operators overlook these essential factors, leading to severe operational issues. Choosing the right hydraulic parts isn't solely about the immediate needs. Reflect on long-term performance and reliability for the best results.

How to Choose the Right Hydraulic Parts for Your Equipment - Factors to Consider When Selecting Hydraulic Parts for Optimal Performance

| Component Type | Material | Pressure Rating (psi) | Temperature Range (°F) | Recommended Use |

|---|---|---|---|---|

| Hydraulic Hoses | Rubber | 3000 | -40 to 212 | General purpose hydraulic applications |

| Hydraulic Cylinders | Steel | 5000 | -20 to 180 | Heavy lifting and industrial machinery |

| Hydraulic Pumps | Cast iron | 4000 | -10 to 150 | Power generation for hydraulic systems |

| Hydraulic Valves | Aluminum | 3000 | -40 to 180 | Control flow in hydraulic circuits |

| Filters | Polyester | 1500 | -10 to 200 | Prevent contamination in hydraulic systems |

Understanding Compatibility and Standards in Hydraulic Components

Choosing the right hydraulic parts is essential for the optimal performance of your equipment.

Compatibility is a key factor to consider. Each hydraulic component, such as pumps, cylinders, and valves, must work seamlessly together. The wrong choice can lead to inefficiencies. It might seem trivial, yet small compatibility issues can cause significant operational problems.

Understanding the standards is equally important. Hydraulic components often follow specific industry standards. These standards ensure interoperability among parts. Always check if the parts meet the relevant standards before purchasing. Not meeting these standards can hurt performance and safety.

Tips: Always consult equipment manuals for specifications. Double-check each component's measurements. Don't overlook the importance of hydraulic fluid types, too. Small details can make a big difference. Compatibility errors can be costly and time-consuming to fix. Reflect on previous choices to avoid repeating mistakes.

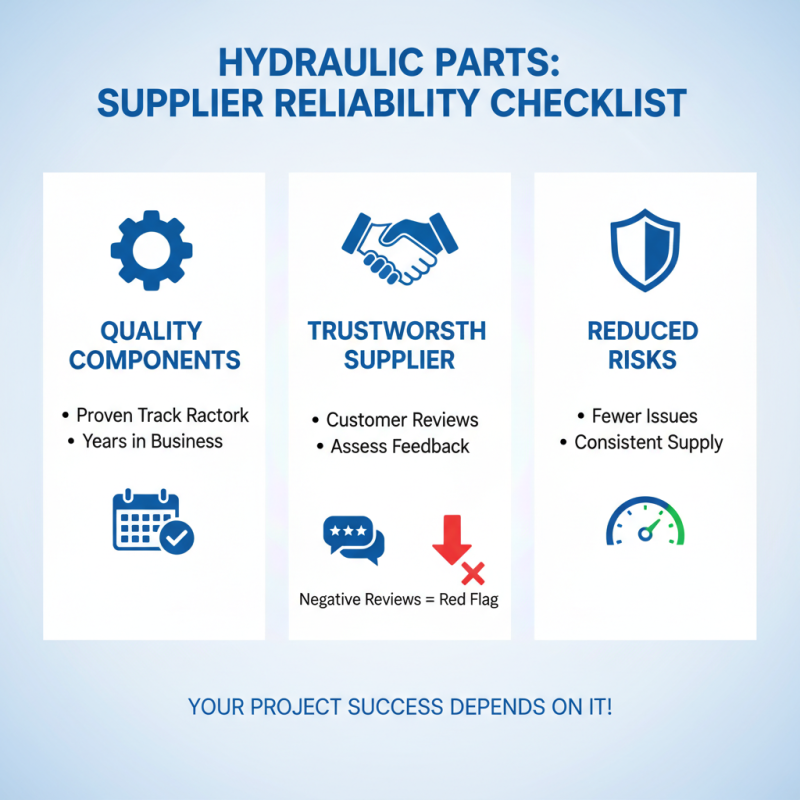

Assessing Supplier Reliability and Product Warranty for Hydraulic Parts

When selecting hydraulic parts, assessing supplier reliability is crucial. A reliable supplier ensures you receive quality components. Look for suppliers with a proven track record. Check their years in business. Newer suppliers may lack experience. It’s essential to read customer reviews. Feedback can reveal potential issues. Negative reviews often indicate reliability problems.

Product warranty is another key factor. A strong warranty signifies confidence in product quality. Suppliers with clear warranties often address defects promptly. Avoid those with vague or limited warranty terms. Understand the coverage details. Some parts may have exclusions that could affect your operations. Be cautious; unclear warranty terms can lead to headaches.

Ask suppliers about their quality control processes. Good suppliers have stringent checks in place. It’s worth investigating how they source materials. Transparency in this area is a positive sign. Don’t hesitate to ask for references. Speak with other customers to gauge their experiences. Engaging with past clients can provide valuable insights.

Related Posts

-

Understanding the Essential Role of Hydraulic Parts in Modern Machinery

-

Unlocking the Future of Machinery: Innovative Trends in Hydraulic Parts for Enhanced Efficiency

-

How to Optimize Pneumatic Hydraulic Systems for Enhanced Performance

-

Unveiling Hydraulic Parts Innovations at the 138th Canton Fair 2025 in China

-

The Ultimate Guide to Understanding Hydraulic Pumps and Motors for Efficient Machinery Performance

-

Understanding the Essential Role of Hydraulic Parts in Modern Machinery

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us