Hydraulic Hose Repair Tips for DIY Success

When it comes to hydraulic hose repair, many DIY enthusiasts face challenges. Understanding the components and tools is crucial. You might think the task is simple, but each step requires careful attention. A small mistake could lead to leaks and potential hazards.

Many people overlook the importance of proper measurements. Using the wrong size can create severe issues. Ensure you have the correct hose and fittings before starting. It's better to double-check than to have to redo your work later.

Additionally, be aware of the materials you are using. Not all hoses are created equal, and the wrong choice may compromise your project. Taking the time to evaluate your options can ensure a successful hydraulic hose repair. Reflecting on common mistakes can lead to better practices in the future.

Understanding Hydraulic Hose Components and Their Function

Hydraulic hoses play a critical role in various machinery. They transport fluid, transferring energy to different components. Understanding the components of these hoses is essential for effective repair and maintenance.

A typical hydraulic hose consists of three main parts: the inner tube, reinforcement layer, and outer cover. The inner tube carries the fluid. The reinforcement layer provides strength and flexibility. The outer cover protects the hose from external factors. Data from industry reports indicate that nearly 40% of hydraulic failures are linked to hose wear and tear. Regular inspections can prevent costly downtime.

Here are some tips for effective repairs. Always check for signs of abrasion or leaks. Clean the area around the hose before inspection. Use the right tools to avoid damage. If you notice a kink or bend, it might reduce flow efficiency. Reflections on past repairs can reveal areas for improvement. Keeping spare hoses can save time in emergencies.

Engaging with these components and their functions allows for a better understanding. Recognizing their role in hydraulic systems can lead to better maintenance practices. Remember, attention to detail can lead to DIY success in hydraulic hose repairs.

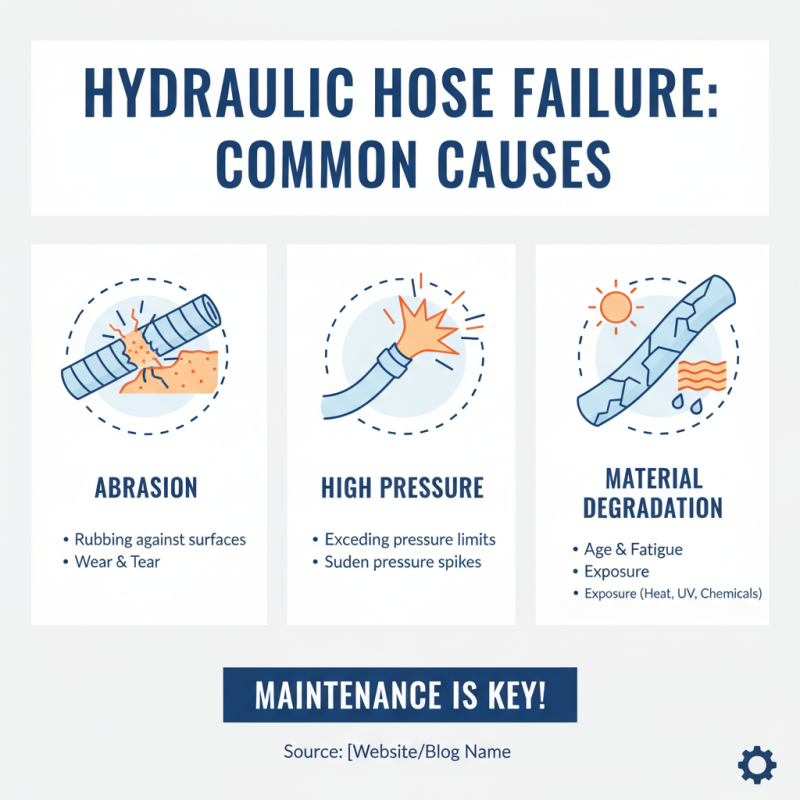

Identifying Common Causes of Hydraulic Hose Failures

Hydraulic hoses are vital for machinery and vehicles, but they can fail for several reasons. One common cause is abrasion. Hoses often rub against surfaces, leading to wear and tear. Additionally, high pressure can cause hoses to burst. Over time, age and exposure to elements can also degrade materials.

When inspecting hoses, look for cracks, bulges, or leaks. These signs indicate potential failures. Do not ignore any visible damage. Regular checks can save time and money. Replace worn-out hoses before they break. Preventive maintenance is key for safety.

Here are some tips for successful repairs: Always clean the area before starting. A dirty surface can lead to poor seals. Use the right tools for cutting and crimping hoses. Inaccurate cuts can compromise the hose's integrity. Lastly, consider using protective sleeves for added durability. This small step can prevent future failures.

Tools and Materials Needed for DIY Hydraulic Hose Repair

When embarking on DIY hydraulic hose repair, the right tools and materials are critical. A good starting point is to gather a hydraulic hose cutter. This tool allows for precise cuttings, ensuring a proper fit. An adjustable wrench or set of wrenches is essential for loosening and tightening connections. Additionally, a crimping tool is necessary for securing fittings to the ends of the hose. According to industry reports, approximately 30% of hydraulic failures are attributed to improper hose fittings.

You'll also need replacement hydraulic hose that meets the required specifications. Many professionals recommend hoses that can withstand at least 3,000 PSI, depending on your project. Rubber or thermoplastic options are available, each with distinct advantages. Don't forget safety gear like goggles and gloves. Working with pressurized systems can be hazardous. Data suggests that nearly 25% of hydraulic accidents occur when proper personal protective equipment is not used.

While assembling your workspace, consider organization. Storing your tools neatly can save time during repairs. However, remember that not all repairs go as planned. Sometimes, the hose may develop leaks even after your best efforts. This indicates a need for further inspection of fittings or the hose itself. Acknowledging these imperfections is part of the learning curve in hydraulic hose repair.

Step-by-Step Procedure for Replacing a Hydraulic Hose

Replacing a hydraulic hose may seem daunting, but with a clear step-by-step procedure, it can be manageable. Begin by safely disconnecting the hydraulic system's power supply. It's crucial to relieve pressure in the system. According to the Fluid Power Trade Association, nearly 20% of hydraulic failures stem from improper installation. This underscores the importance of following directions carefully.

Next, use the right tools to remove the old hose. A wrench and a cutting tool are essential here. Measure the length of the new hose accurately to avoid leaks. Tip: Always double-check the compatibility of the hose with the system. A mismatched hose can lead to catastrophic failures down the road.

Once the new hose is secured, slowly restore the system’s pressure. Observe for any leaks at the joints. If there’s any irregularity, reassess the fittings. It’s easy to overlook minor details, yet those details often lead to the most significant issues. A diligent inspection post-replacement not only ensures safety but enhances the longevity of the hydraulic system.

Preventive Maintenance Tips for Hydraulic Hose Longevity

Regular preventive maintenance can significantly extend the life of hydraulic hoses. Inspect your hoses frequently for signs of wear. Look for cracks, bulges, or leaks that may indicate damage. A small issue can lead to bigger problems down the line.

Tips for maintaining your hydraulic hoses include keeping them clean and free of debris. Use a soft brush to remove dirt. Avoid harsh chemicals that can degrade the rubber. Additionally, ensure proper routing of hoses to prevent unnecessary strain. Hoses should not rub against each other or sharp edges.

Be aware of the environment where your hoses operate. Extreme temperatures can affect performance. If working in fluctuating conditions, check your hoses more often. Remember, preventive maintenance is cheaper than repairs. Small efforts can lead to big savings.

Related Posts

-

5 Essential Tips for Choosing the Right Hydraulic Pump Motor for Your Industrial Needs

-

Ultimate Checklist for Efficient Hydraulic Pump Repair Maintenance

-

Understanding the Power Behind Fluid Power Hydraulics in Everyday Machines

-

How to Choose the Right Gas Powered Hydraulic Pump for Your Needs

-

Top 10 Benefits of Hydraulic Systems for Modern Machinery Efficiency

-

Unlocking Efficiency: The Ultimate Guide to Hydraulic Power Packs for Modern Applications

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us