How to Effectively Perform Hydraulic Hose Repair for Optimal Performance?

In the world of hydraulic systems, the importance of hydraulic hose repair cannot be overstated. Expert Mike Henderson, a renowned specialist in hydraulic maintenance, has noted, "A well-maintained hose can prevent costly breakdowns and downtime." This statement highlights the critical role of proper repair techniques in ensuring optimal performance.

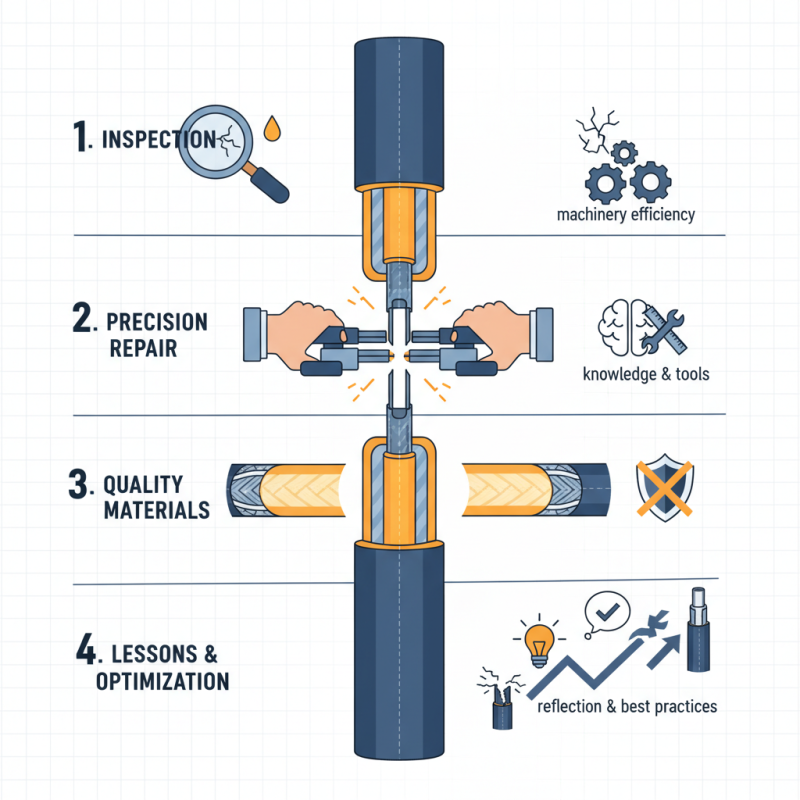

Hydraulic hoses endure significant stress and wear over time. Regular inspection is essential to identify potential leaks or structural issues. A small tear can lead to major failures, impacting overall machinery efficiency. The repair process demands precision and understanding of hydraulic dynamics. Without proper tools and knowledge, repairs can result in further complications.

Many operators underestimate the complexity of hydraulic hose repair. It is not merely a quick fix. It requires attention to detail and a commitment to safety. Using subpar materials or improper techniques often leads to recurring problems. Reflection on past repairs can yield valuable lessons for future maintenance. A focus on quality and best practices ensures longevity in hydraulic applications.

Understanding the Importance of Hydraulic Hose Repair for Performance

Hydraulic hoses play a critical role in machinery performance. Regular maintenance and timely repairs are essential for optimal function. A worn or leaking hose can lead to significant efficiency losses. These small components carry powerful fluids under high pressure. Any failure can disrupt operations and increase costs.

Ignoring minor issues can lead to worse outcomes. A small leak might seem trivial, but it can escalate quickly. Over time, hydraulic fluid loss results in inadequate pressure. This can create operational delays and even equipment damage. Employees might work harder, but productivity declines.

Understanding hose repair is key. It involves inspecting for abrasions, kinks, or signs of wear. Proper techniques and materials can make a big difference. DIY repairs can save money, but mistakes can be costly. Educating staff on proper handling is essential. Regular training can prevent future problems and ensure longevity. The goal is to maintain performance while minimizing risks.

How to Effectively Perform Hydraulic Hose Repair for Optimal Performance?

| Repair Method | Estimated Time (hrs) | Cost (USD) | Tools Required | Performance Impact |

|---|---|---|---|---|

| Reinforcement Replacement | 1.5 | 150 | Cutting Tool, Hose Clamps | High |

| Seal Replacement | 1 | 100 | Wrench, Sealing Compound | Medium |

| Hose Assembly | 2 | 200 | Hose Crimper, Measuring Tape | Very High |

| Leak Testing | 0.5 | 50 | Pressure Gauge, Soap Solution | Critical |

| End Fitting Replacement | 1 | 80 | Torque Wrench, Pliers | High |

Assessing Damage: Identifying When Hydraulic Hose Repair is Necessary

Hydraulic hoses are critical in many industrial applications. Regular inspections help identify when repairs are necessary. Look for cracks, leaks, or bulges on the hose. A study by the Hydraulic Institute states that 30% of hydraulic system failures are due to hose issues. If you see signs of wear, don’t ignore them. Early detection can save significant downtime.

Tips:

Always maintain a log of hose performance. Track any signs of leaks or decreased pressure. This information is vital for effective repairs.

When assessing damage, consider the age of the hose. Most hoses last between 5 to 10 years, depending on usage. After this period, they are more prone to failures. If the hose has visible damage, replacement may be the best option. Repairing may only be a temporary solution, leading to further issues.

Tips:

Keep replacement hoses on hand. This reduces downtime during emergencies. Also, training your staff on hose inspections can improve system reliability. Remember, a proactive maintenance strategy goes a long way in ensuring optimal performance.

Step-by-Step Guide to Proper Hydraulic Hose Repair Techniques

Hydraulic hose repair is crucial for maintaining equipment efficiency. Proper techniques can extend hose lifespan. According to industry reports, about 70% of hydraulic failures stem from hose issues. Timely repair helps avoid costly downtimes.

To start with, assess the hose for visible damage. Look for cracks, abrasions, or leaks. Do not underestimate minor signs; they often indicate deeper problems. Use the correct tools for cutting and crimping the replacement hose. Precision is key. A poorly crimped connection may fail under pressure.

After preparation, clean the replacement hose thoroughly. Debris can compromise the new connection. When installing, ensure proper alignment. Misalignment causes stress and premature failure. Regular training on repair techniques can reduce errors. Studies show teams trained in hose repair see a 35% reduction in failures. Consider documenting each repair for future reference. This way, patterns can be spotted, leading to better practices.

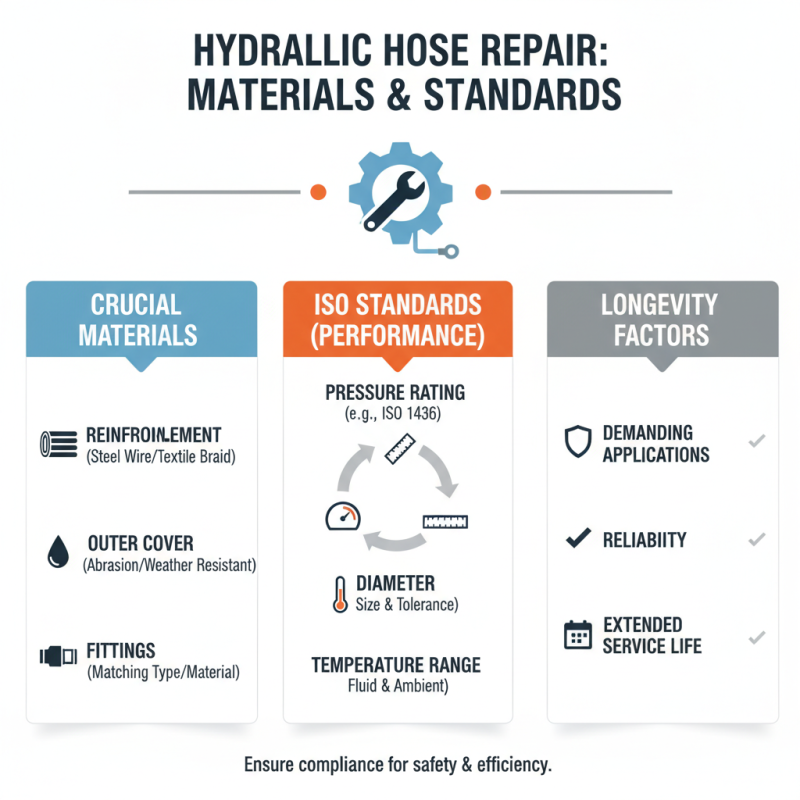

Selecting the Right Materials: Hose Specifications and Standards

When it comes to hydraulic hose repair, selecting the right materials is crucial. The specifications and standards of hoses determine their performance and longevity. According to the International Organization for Standardization (ISO), hoses must meet specific requirements based on pressure, diameter, and temperature. This helps ensure they can withstand demanding applications.

Choosing hoses made from high-quality materials is essential. For instance, rubber hoses work well in environments with high flexibility needs. Meanwhile, thermoplastic hoses can offer resistance to abrasions. Reports show that 30% of hose failures are linked to improper material choices. It's vital to consider environmental factors like chemical exposure and UV resistance when selecting hoses.

Some technicians overlook hose specifications, leading to premature failures. A lack of understanding can result in using hoses that are too small or not suited for the application. Regular maintenance checks can reduce these failures. Ensuring your hoses are up to standard is as important as selecting them. The right materials can significantly enhance performance and reduce repair costs over time.

Maintenance Practices to Enhance Hydraulic Hose Longevity and Efficiency

Hydraulic hoses are critical components in many machines. Regular maintenance is crucial for maximizing their longevity and efficiency. According to industry reports, the failure of hydraulic hoses can lead to costly downtime. A good practice is to inspect hoses weekly. Look for abrasions, cracks, or bulges. These small issues can turn into major problems if not addressed.

Using proper fittings is essential. Incorrect fittings can create stress points and lead to premature wear. Choose materials that match the hose specifications. A study by the Hydraulic Institute shows that mismatched components increase the risk of failure by 30%. Implementing a routine maintenance schedule helps in identifying potential failures early. However, ignoring this can lead to catastrophic failures.

It’s important to keep hoses clean and free from debris. Dirt and contaminants can compromise hose integrity. A report indicates that 70% of hydraulic failures are due to contamination. Also, ensure that hoses are not exposed to extreme temperatures. Close monitoring and documentation of hose conditions can enhance reliability. Neglecting these practices often leads to unexpected downtime and repair costs.

Hydraulic Hose Repair and Maintenance Practices

This chart illustrates the effectiveness ratings of various maintenance practices for hydraulic hose repair. Regular inspections and the replacement of worn hoses scored the highest, indicating their critical role in enhancing hydraulic hose longevity and efficiency.

Related Posts

-

Hydraulic Hose Repair Tips for DIY Success

-

Unlocking Hydraulic Repair Excellence A Comprehensive Guide to Efficient Solutions

-

How to Effectively Perform Hydraulic Repair: Step-by-Step Guide for Beginners

-

10 Best Hydraulic Cylinder Parts You Should Know

-

Pneumatic Hydraulics Versus Traditional Hydraulics A Comprehensive Comparison of Efficiency and Performance

-

The Ultimate Guide to Understanding Hydraulic Pumps and Motors for Efficient Machinery Performance

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us