What is Hydraulic Fluid and Why is it Important?

Hydraulic fluid plays a vital role in various industrial applications. It is often seen as the blood that powers hydraulic systems. John Smith, a hydraulic fluid expert, states, "Without the right fluid, a hydraulic system cannot function effectively." His words edge us into understanding the importance of hydraulic fluid.

Hydraulic fluid serves multiple purposes beyond mere transmission of power. It lubricates, cools, and protects the hydraulic system. Most people overlook the significance of choosing the right hydraulic fluid. This choice impacts system efficiency and longevity. Without proper fluid, machinery can suffer damage or reduce productivity—a costly outcome.

Many industries rely heavily on hydraulic systems. Construction, manufacturing, and automotive sectors depend on hydraulic fluid for smooth operations. However, not all fluids are created equal. Understanding the intricacies and choosing suitable options can be challenging. It requires careful thought and consideration. A mistake in selection may lead to performance issues, making this topic worthy of discussion.

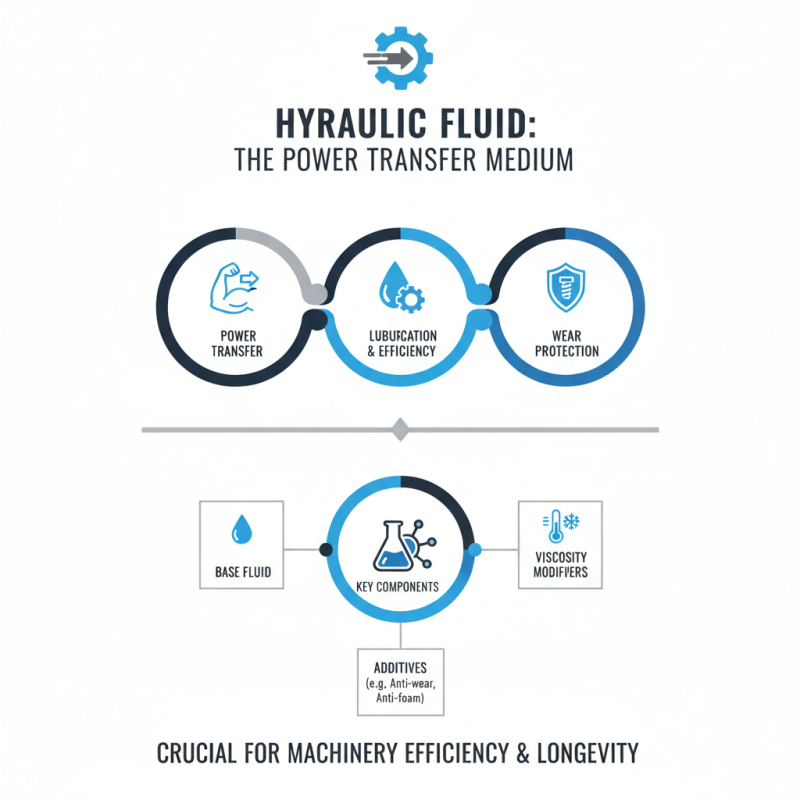

Definition of Hydraulic Fluid and Its Composition

Hydraulic fluid is a crucial component in many machinery applications. It acts as the medium that transfers power in hydraulic systems. The composition of hydraulic fluid typically includes several key elements. These components can ensure efficiency, lubrication, and protection against wear.

Most hydraulic fluids are made from mineral oil, which is derived from crude oil. The oil is refined and treated to enhance its properties. Additives are often included to improve performance. These additional substances can help prevent rust, reduce foaming, and inhibit oxidation. Water can also be present in some hydraulic fluids, but it must be carefully controlled to avoid corrosion.

Understanding the composition of hydraulic fluid is essential. It directly influences the reliability of hydraulic systems. Even slight variations in formulation can lead to performance issues. For instance, if the fluid lacks adequate additives, it may cause serious problems over time. Maintenance teams must monitor fluid quality regularly. This proactive approach can save resources and prevent costly downtime.

Types of Hydraulic Fluids and Their Applications

Hydraulic fluids are crucial for many industrial applications. They enable machinery to operate smoothly and efficiently. Different types of hydraulic fluids exist, and each serves a specific purpose.

Mineral oils are the most common hydraulic fluids. They offer good lubrication and heat transfer. However, they can suffer from oxidation over time. This can lead to sludge buildup. It’s essential to monitor their condition regularly.

Water-based fluids are also used. They have lower flammability risks. Yet, they can cause rust and corrosion. Proper storage and maintenance are vital to prolong their life.

Tips: Always check for leaks. A small leak can lead to significant fluid loss. Additionally, ensure you use the right fluid type for your machinery. Mismatched fluids can cause damage. Finally, remember to change your hydraulic fluid as needed. Neglecting this can lead to equipment failure.

Role of Hydraulic Fluid in Machinery Performance

Hydraulic fluid plays a crucial role in the performance of machinery. It acts as a medium for power transfer. Without proper hydraulic fluid, machinery can fail to operate efficiently. This fluid must maintain specific properties, such as viscosity and chemical stability, to function effectively. Poor quality or incorrect fluid can lead to decreased performance.

In machinery, hydraulic fluid lubricates components, preventing wear and tear. It also helps in heat dissipation, keeping temperatures in check. For optimal performance, regular checks of the fluid level and quality are necessary. Dirty or contaminated fluid can impair function and lead to costly repairs.

Tip: Always consult your machinery's manual for recommended fluid types. This small step can save time and money.

Selecting the right hydraulic fluid is not just about performance; it impacts safety as well. Leaks or failures can create hazardous situations. Observing changes in machine behavior may indicate fluid issues. Look for signs like unusual noises or slow response times.

Tip: Regularly monitor machinery for signs of wear. Early detection can prevent major breakdowns.

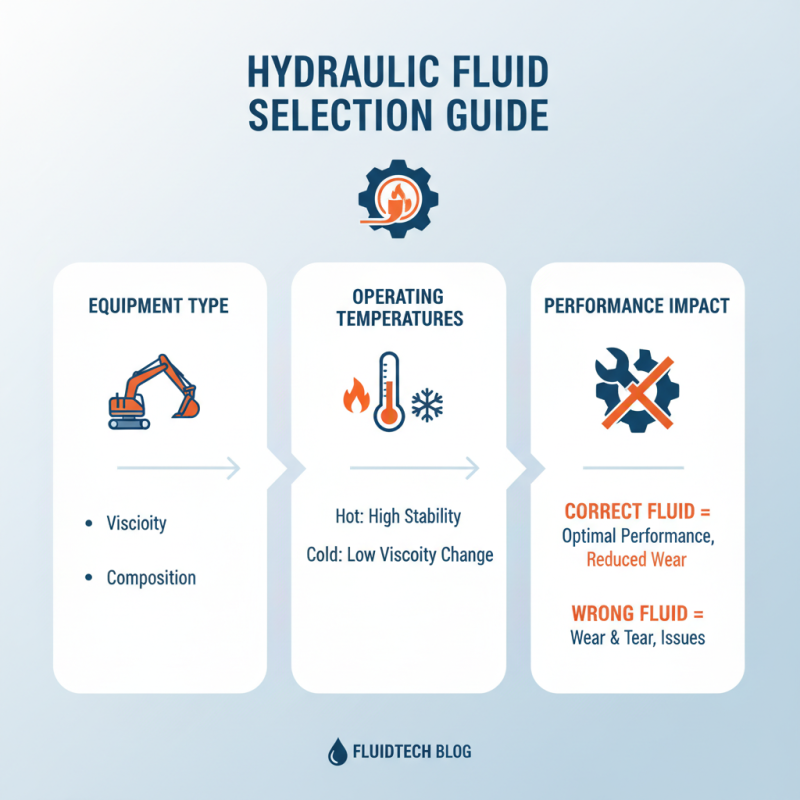

Factors Influencing Hydraulic Fluid Selection

When selecting hydraulic fluid, several factors come into play. The type of equipment dictates the fluid's viscosity and composition. Machines operating in extreme temperatures require fluids that can perform optimally in both hot and cold conditions. For instance, using the wrong viscosity can lead to equipment wear and performance issues.

The environment also influences fluid choice. Some fluids are designed for high biodegradability, which is great for eco-conscious operators. However, these fluids may not always offer the same performance under heavy loads. It’s a balancing act that can result in trade-offs between environmental concerns and machine efficiency.

Another crucial aspect is the compatibility with seals and materials. Fluids can degrade seals, leading to leaks and increased maintenance costs. It's easy to overlook this detail during selection. Sometimes, the cheapest option can lead to higher long-term expenses. Making an informed decision can prevent these issues. Observing how different fluids perform in the real world is vital for determining the best choice.

Maintenance and Safety Considerations for Hydraulic Fluids

Hydraulic fluids are crucial in many industrial systems. They help in transferring energy efficiently. However, their maintenance is often overlooked. Proper upkeep can prevent costly breakdowns and accidents.

Regularly checking fluid levels is essential. Low fluid levels can lead to increased wear and tear. Routine inspections for leaks are equally important. Even a small leak can result in significant losses. Many forget that fluid contamination can also happen. This can hinder the system's performance and shorten its lifespan.

Safety measures should always be a priority. Wearing protective equipment when handling hydraulic fluids is a must. Spills should be cleaned immediately to avoid slips and contamination. Training employees on proper handling techniques can also reduce risks. It’s easy to be complacent, but neglecting these aspects can have serious consequences. Reflecting on these practices can lead to better maintenance and a safer work environment.

What is Hydraulic Fluid and Why is it Important? - Maintenance and Safety Considerations for Hydraulic Fluids

| Property | Description | Importance |

|---|---|---|

| Viscosity | A measure of a fluid's resistance to flow. | Critical for efficient operation and system performance. |

| Thermal Stability | The ability of hydraulic fluid to maintain performance under temperature variations. | Prevents degradation and maintains safety over a wide temperature range. |

| Corrosion Resistance | The capacity to resist oxidative wear and corrosion. | Extends the life of hydraulic components and reduces maintenance costs. |

| Fire Resistance | Hydraulic fluids designed to withstand high temperatures and ignition. | Enhances safety in high-risk environments. |

| Biodegradability | The ability of a fluid to decompose naturally in the environment. | Minimizes environmental impact and aligns with sustainability practices. |

Related Posts

-

7 Compelling Reasons to Choose Fluid Power Hydraulics for Your Industrial Needs

-

The Essential Guide to Choosing the Right Hydraulic Oil for Optimal Machinery Performance

-

How to Optimize Pneumatic Hydraulic Systems for Enhanced Performance

-

Top 10 Benefits of Hydraulic Systems for Modern Machinery Efficiency

-

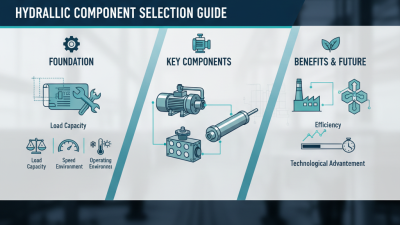

How to Choose the Right Hydraulic Components for Your Applications

-

Unlocking Hydraulic Repair Excellence A Comprehensive Guide to Efficient Solutions

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us