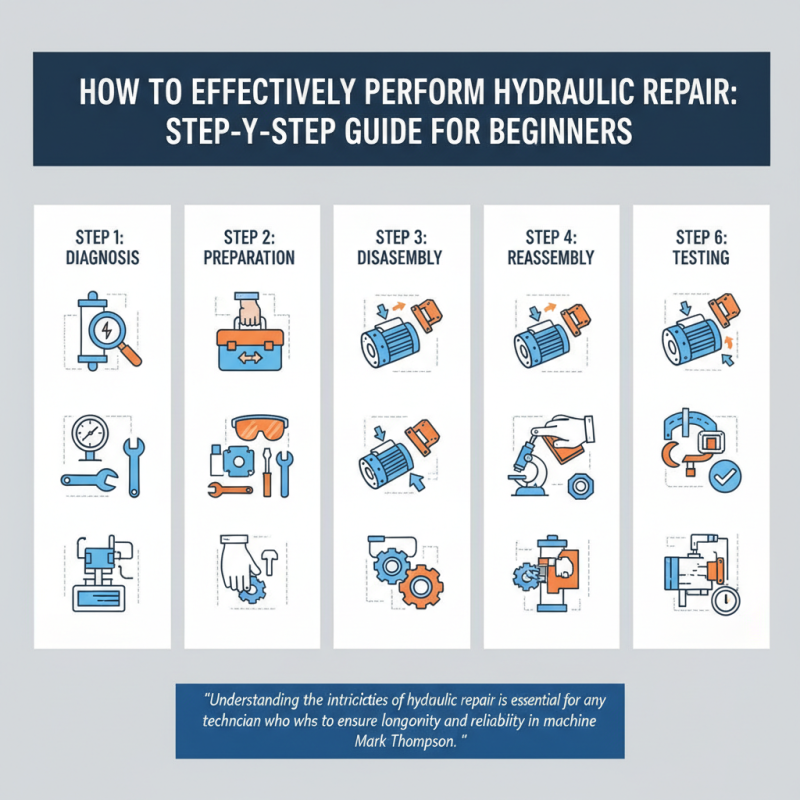

How to Effectively Perform Hydraulic Repair: Step-by-Step Guide for Beginners

Hydraulic repair is a crucial skill in the field of machinery maintenance, often determining the operational efficiency and safety of hydraulic systems. As Mark Thompson, a renowned expert in hydraulic engineering, once said, "Understanding the intricacies of hydraulic repair is essential for any technician who wants to ensure longevity and reliability in machine performance." This sentiment captures the essence of why mastering hydraulic repair techniques is not just beneficial, but necessary for beginners venturing into this technical domain.

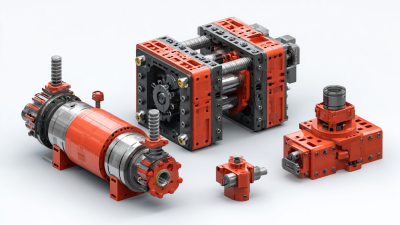

In this step-by-step guide, we will explore the fundamental principles and practices involved in hydraulic repair. From diagnosing issues to executing effective repair strategies, we will provide insights tailored for those new to the field. Each step will be presented clearly, enabling novices to grasp the critical aspects of hydraulic systems, ultimately empowering them to tackle repairs with confidence and competence. Whether you are working with hydraulic cylinders, pumps, or valves, understanding the repair process will significantly enhance your ability to maintain these vital components in various machinery applications.

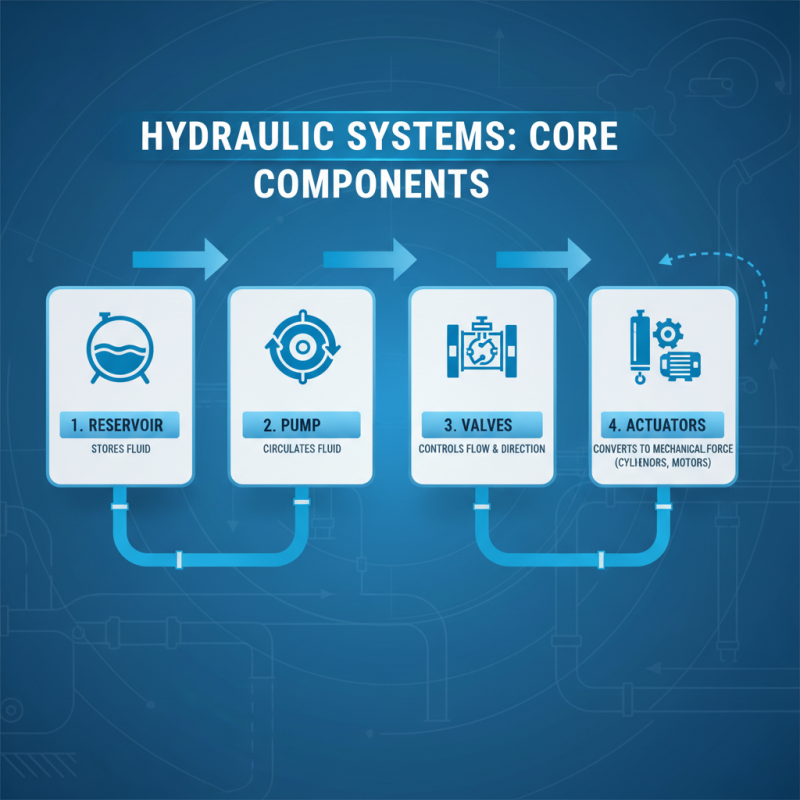

Understanding Hydraulic Systems: Components and Functionality

Hydraulic systems are intricate networks that utilize fluid power to perform a wide range of tasks, from operating heavy machinery to controlling automotive braking systems. At the core of these systems are several essential components. The reservoir stores hydraulic fluid, while the pump circulates it throughout the system. Valves control the flow and direction of the fluid, ensuring that the desired motion is achieved. Finally, actuators, such as hydraulic cylinders or motors, convert the hydraulic energy back into mechanical force, allowing machines to perform their functions effectively.

Understanding the functionality of each component is crucial for anyone looking to perform hydraulic repairs. The hydraulic fluid, typically a specialized oil, plays a vital role in lubricating parts and maintaining pressure within the system. When diagnosing issues, recognizing symptoms like leaks, unusual noises, or erratic movement can lead to identifying which component may be malfunctioning. For example, a leaking reservoir may indicate a broken seal, while inconsistent flow could point to a clogged filter. By comprehensively grasping these elements and their interconnections, beginners can approach hydraulic repair with confidence and accuracy, ensuring that systems remain operational and efficient.

Common Issues in Hydraulic Systems and Their Causes

Hydraulic systems are integral to a variety of machinery and vehicles, but they can encounter several common issues that can impede performance. One prevalent problem is fluid leaks, which often arise from worn seals, loose fittings, or damaged hoses. Identifying the source of the leak is crucial, as even a small loss of hydraulic fluid can lead to significant drops in system efficiency and pressure.

Another typical issue is air contamination within the hydraulic fluid, which can cause erratic system performance, including sluggish or jerky movements. This contamination often occurs due to improper fluid changes or poorly sealed components. Regular maintenance and ensuring proper sealing are essential steps in preventing air from infiltrating the system.

Lastly, overheating is a common problem that can severely damage hydraulic systems. Overheating typically results from excessive fluid viscosity, prolonged use under heavy loads, or insufficient cooling mechanisms. Ensuring adequate coolant flow and monitoring the fluid temperature are vital to maintaining optimal operating conditions and preventing long-term damage. Understanding these common issues and their causes is the first step in effectively performing hydraulic repairs.

Step-by-Step Diagnostic Procedures for Hydraulic Repairs

When performing hydraulic repairs, following a structured diagnostic procedure is crucial for identifying issues accurately and efficiently. The first step in this process is to observe the symptoms of the hydraulic system's malfunction. Begin by checking for leaks, unusual noises, or changes in pressure. Gathering this initial information will help establish a clear starting point for further investigation. Document any irregularities, as this will create a reference for the repair process.

Next, proceed with a systematic inspection of the hydraulic components. Start at the power source, ensuring that the pump functions properly and that there is adequate fluid levels. Examine hoses and fittings for wear or obstructions, as these can often lead to performance issues. Additionally, check the valves and cylinders, testing their responsiveness and integrity. If any component exhibits signs of damage or failure, note it for replacement. By performing these diagnostic steps methodically, you can isolate the specific issue within the hydraulic system, paving the way for effective repairs.

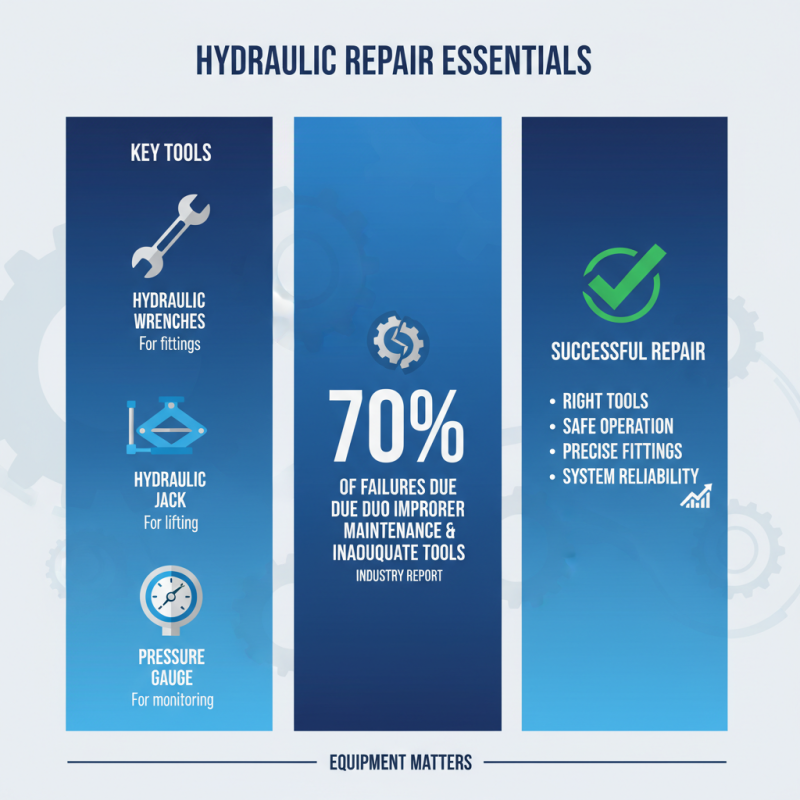

Essential Tools and Equipment for Hydraulic Repair

When preparing for hydraulic repair, having the right tools and equipment is crucial for ensuring a successful repair process. Essential tools include hydraulic wrenches, which are vital for loosening and tightening hydraulic fittings without damaging them. Additionally, a quality hydraulic jack is necessary for safely lifting heavy components, while a pressure gauge helps in monitoring system pressures to prevent overloading. According to industry reports, nearly 70% of hydraulic system failures can be traced back to improper maintenance and inadequate tools, highlighting the importance of being well-equipped.

Another key piece of equipment is the hydraulic fluid extractor, which allows for the safe removal of old or contaminated hydraulic fluid. Using a portable oil filter can help keep your hydraulic fluid clean, minimizing wear on components. Industry data shows that investing in high-quality maintenance tools can extend the lifespan of hydraulic systems by over 30%, significantly reducing overall repair costs.

Tips: Always keep a well-organized workspace. Ensure that your tools are easily accessible and free of any debris to facilitate a smoother repair process. Familiarize yourself with each tool's manual and operational guidelines to maximize their effectiveness while minimizing risks.

Maintenance Best Practices to Prevent Hydraulic Failures

Preventing hydraulic failures requires a proactive maintenance approach that focuses on regular inspections, cleanliness, and proper fluid management. Establish a routine schedule to check all hydraulic systems for leaks, wear, and abnormal sounds. Early detection of potential problems can save time and resources, avoiding more severe issues down the line. Additionally, ensure that all hydraulic components, including hoses, fittings, and pumps, are kept clean and free of contaminants, as dirt and debris can cause significant damage over time.

Tips: Always use filters to clean hydraulic fluid and replace them according to the manufacturer’s recommendations. Implementing a fluid analysis program can further help detect contamination and signs of wear. Regularly changing the hydraulic fluid will not only extend the lifespan of your equipment but also ensure optimal performance.

Another crucial aspect of maintenance is to monitor the hydraulic fluid levels and quality consistently. Insufficient fluid can lead to overheating and eventual system failure. Make it a practice to check fluid levels before starting any work. Furthermore, consider training your team on recognizing signs of hydraulic system distress—early intervention can be the key to preventing breakdowns and ensuring a safe working environment. By emphasizing these best practices, you can significantly extend the life of your hydraulic systems and avoid costly repairs.

Related Posts

-

Unlocking Hydraulic Repair Excellence A Comprehensive Guide to Efficient Solutions

-

Top 10 Hydraulic Equipment You Need for Your Business Success

-

Unlocking the Future of Machinery: Innovative Trends in Hydraulic Parts for Enhanced Efficiency

-

The Ultimate Guide to Electric Hydraulic Pumps in 2025 Trends and Innovations

-

How to Optimize Air Hydraulic Pump Performance for Maximum Efficiency

-

The Essential Guide to Choosing the Right Hydraulic Oil for Optimal Machinery Performance

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us