Top Differences Between Pneumatic and Hydraulic Systems?

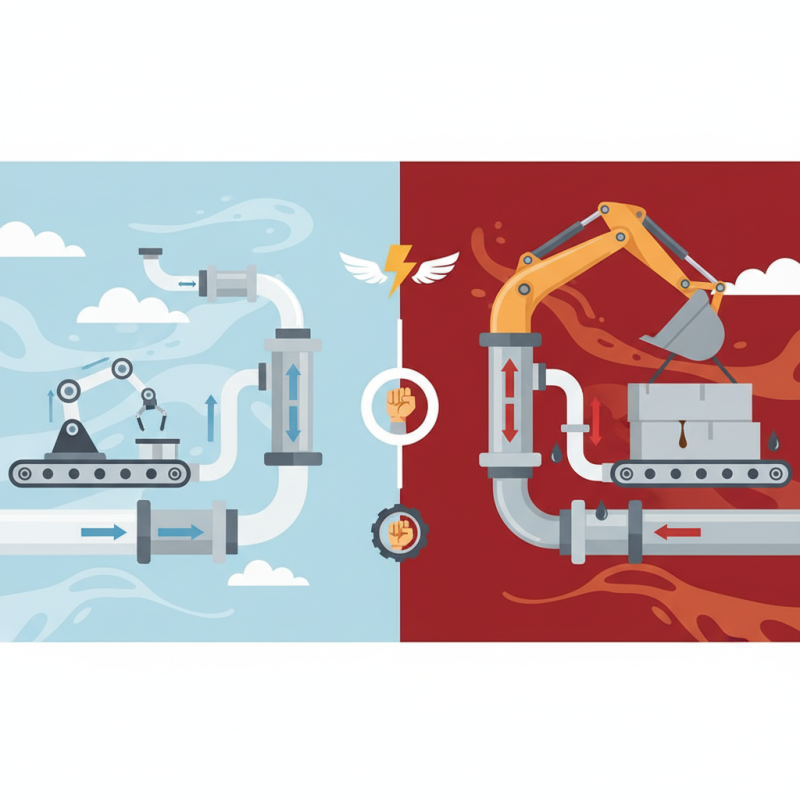

When comparing pneumatic and hydraulic systems, it’s essential to understand their distinct characteristics. Both systems are integral to many industrial processes, yet they function in fundamentally different ways. Pneumatic systems use compressed air to create movement, while hydraulic systems rely on pressurized liquid. This difference in medium results in a variety of applications.

Pneumatic systems are often lighter and can operate in environments where fluid leaks could be disastrous. In contrast, hydraulic systems generate higher force and are preferred for heavy-duty tasks. However, hydraulic leaks can be messy and hazardous, raising concerns about workplace safety.

The choice between pneumatic and hydraulic systems hinges on specific needs. Factors such as power, speed, and responsiveness play crucial roles. Understanding these differences is vital for engineers and decision-makers. Both systems have unique advantages and challenges, making their comparison a topic worthy of deeper exploration.

Differences in Energy Transmission: Pneumatic vs. Hydraulic Systems

Pneumatic and hydraulic systems transmit energy in distinct ways. Pneumatic systems utilize compressed air, while hydraulic systems rely on pressurized liquids. This fundamental difference leads to various implications for their uses. For instance, pneumatic systems are lighter and often preferred in applications requiring speed. On the other hand, hydraulic systems provide more power and can handle heavier loads.

The efficiency of these systems also differs significantly. Pneumatic energy transmission is less efficient due to air compressibility. Leaks in the air provided create losses. Hydraulic fluids, while they can also leak, are generally more controllable. This makes hydraulic systems more suited for tasks that need precision. However, maintenance can become a chore. Fluid leakage can spoil equipment and create hazards.

Operational environments play a crucial role too. Pneumatic systems work well in clean and dry conditions. However, any moisture can lead to performance issues. Hydraulic systems can function in more diverse environments. Still, they may require extensive safety measures due to fluid hazards. Each system has unique strengths and challenges, impacting their application in real-world settings.

Top Differences Between Pneumatic and Hydraulic Systems

| Characteristic | Pneumatic Systems | Hydraulic Systems |

|---|---|---|

| Fluid Used | Compressed Air | Liquid (Oil or Water) |

| Energy Density | Lower Energy Density | Higher Energy Density |

| Speed of Operation | Faster Response Time | Slower Response Time |

| Control Complexity | Simple Control Systems | More Complex Control Systems |

| Maintenance | Lower Maintenance Requirements | Higher Maintenance Requirements |

| Applications | Lightweight Applications | Heavy-Duty Applications |

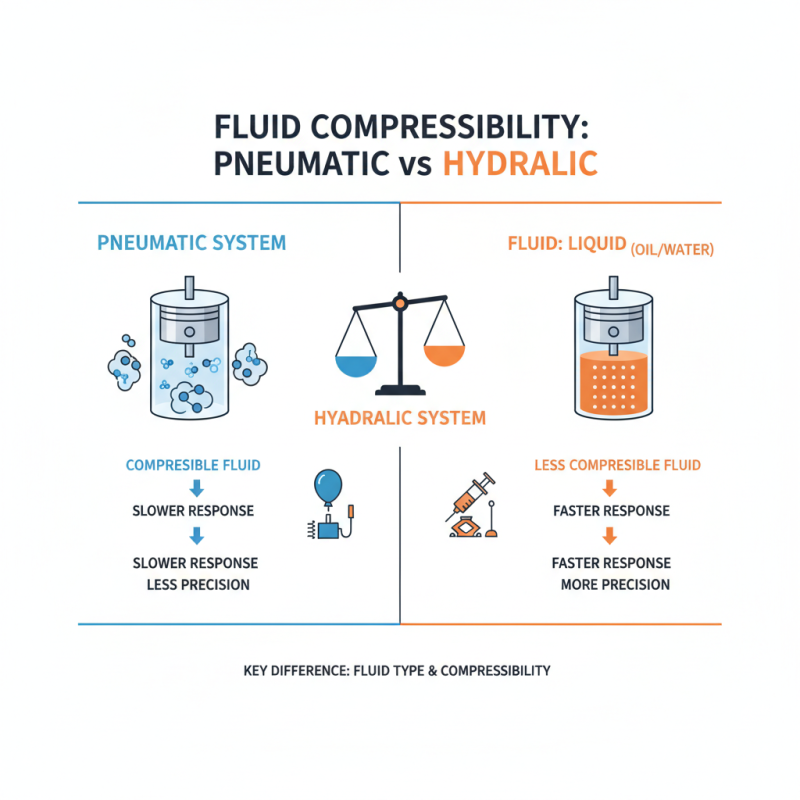

Compressibility of Fluids: Impact on Performance and Control

When comparing pneumatic and hydraulic systems, one key difference lies in the compressibility of fluids. Pneumatic systems use air or gas, while hydraulic systems rely on liquids. Compressibility impacts performance significantly. Gases can expand and compress easily, leading to potential delays in response. Liquids, however, are less compressible. This often results in faster, more precise movements.

In a pneumatic system, the air pressure can fluctuate rapidly, which may compromise control. Such fluctuations can cause issues in applications requiring fine motion. Conversely, hydraulic systems maintain a steady pressure. This stability ensures smoother and more consistent operation, essential in heavy machinery.

**Tip:** Always consider the application requirements. If precision is crucial, hydraulic systems may be the better choice. For simpler tasks, pneumatically powered systems can suffice.

Using pneumatic systems can sometimes lead to inefficiencies. Air leaks or pressure drops can hinder performance. Regular maintenance is vital to mitigate these issues. Ensuring proper seals and connections helps maintain optimal performance.

**Tip:** Monitor fluid or air levels consistently. A little attention can save time and money in the long run.

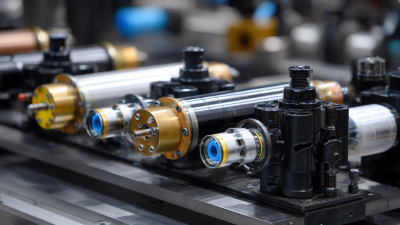

Pressure Levels: Hydraulic Systems vs. Pneumatic Systems Comparisons

When comparing hydraulic and pneumatic systems, pressure levels play a crucial role. Hydraulic systems operate at significantly higher pressure levels, often exceeding 3,000 psi. This high pressure allows for powerful force generation, making them ideal for heavy lifting applications. Pneumatic systems, on the other hand, typically operate around 80 to 100 psi. This lower pressure means they are better suited for tasks that require quick movements rather than heavy loads.

This difference in pressure levels also affects the design of each system. Hydraulic components are usually more robust and heavier. They must withstand higher forces without failure. Pneumatic systems are lighter and simpler. However, they have limitations in force and precision. This can lead to frustrations in applications where accuracy is essential.

Moreover, the pressure levels impact safety aspects. High-pressure hydraulics carry risks of leaks or failures, which can lead to injuries. Meanwhile, pneumatic systems, while safer regarding pressure, can still pose risks, such as sudden air release. Both systems have unique challenges that require careful consideration in design and implementation. It's essential to reflect on these differences to choose the right system for specific needs.

Applications in Industry: Where Pneumatics and Hydraulics Shine

Pneumatic and hydraulic systems are essential in many industries. Each type has unique uses.

Pneumatics often shine in applications requiring speed and lightness.

Tools like air compressors and spray guns effectively use compressed air. They excel in assembly lines and packaging industries.

However, they might lack in precision when compared to hydraulics.

Hydraulics are powerful and ideal for heavy lifting.

Think of construction equipment like jacks and excavators. These machines utilize high pressure to move large loads.

However, they can be slower and heavier. This means that while they provide strength, they also may take more time to set up and operate.

Tip: Consider the workspace. Pneumatic systems may require more maintenance due to moisture in the air.

Hydraulic systems, while strong, can leak fluids. Regular checks can prevent issues. Use appropriate lubricants to enhance system life and performance.

Balancing the needs of speed and strength is key in making the right choice.

Cost and Maintenance Considerations for Pneumatic and Hydraulic Systems

When comparing pneumatic and hydraulic systems, cost and maintenance are crucial factors. Pneumatic systems are generally less expensive to install and run. They use compressed air, which is abundant and affordable. This can lead to lower operational costs. However, compressed air systems can be less energy-efficient. Air leaks are common, which can increase expenses over time. Regular checks are necessary to maintain efficiency.

Hydraulic systems, on the other hand, often have higher initial costs. They utilize fluids under pressure, which can provide significant power. Maintenance for hydraulics can involve more intricate and costly repairs. Fluid leaks may lead to environmental hazards, adding to their complexity. While hydraulic systems can offer better performance in heavy-duty applications, they require vigilant upkeep. This means regular checks and potentially higher costs.

Ultimately, the choice between these systems may depend on the specific requirements of the application. Neither system is perfect, and each has strengths and weaknesses. The decision should weigh not just the initial costs but also ongoing maintenance needs. This reflection can lead to smarter choices in system selection.

Cost and Maintenance Comparison of Pneumatic and Hydraulic Systems

Related Posts

-

Essential Pneumatic Hydraulic Maintenance Checklist for Optimal Performance

-

2026 Top Trends in Pneumatic and Hydraulic Technology?

-

Understanding the Importance of Hydraulic Components in Modern Machinery

-

How to Choose the Right Hydraulic Components for Your Applications

-

10 Essential Tips for Mastering Pneumatic and Hydraulic Systems

-

Pneumatic Hydraulics Versus Traditional Hydraulics A Comprehensive Comparison of Efficiency and Performance

Choose a global leader for your hydraulics solutions

How can we help you?

Call to 0034 943884600 Contact us